Latest Blogs

Carbide Inserts for Aluminum: Which Type Works Best?

"Explore the best carbide inserts for aluminum machining. Learn ISO codes, coatings, chip breakers, and top brands like Sandvik, Kennametal & Iscar."

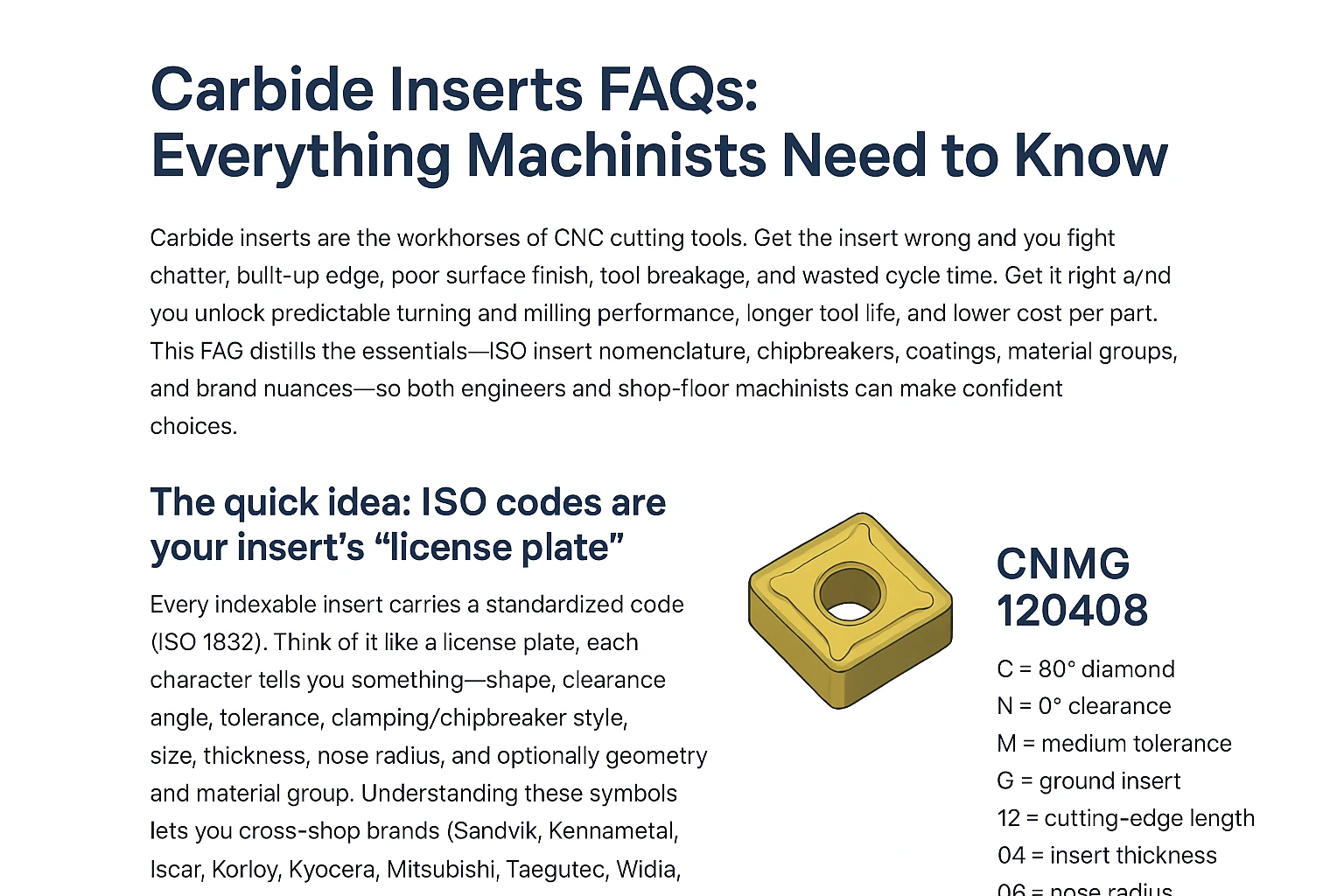

Carbide Inserts FAQs: Everything Machinists Need to Know

Carbide inserts are the backbone of modern CNC machining, but choosing the right insert can be confusing. This comprehensive FAQ explains everything machinists need to know—ISO insert nomenclatu...

Best Carbide Inserts for Stainless Steel Machining

Stainless steel is everywhere — medical implants, automotive components, aerospace parts and food-grade fittings — and it’s notoriously fussy to cut. Choosing the right carbide inser...

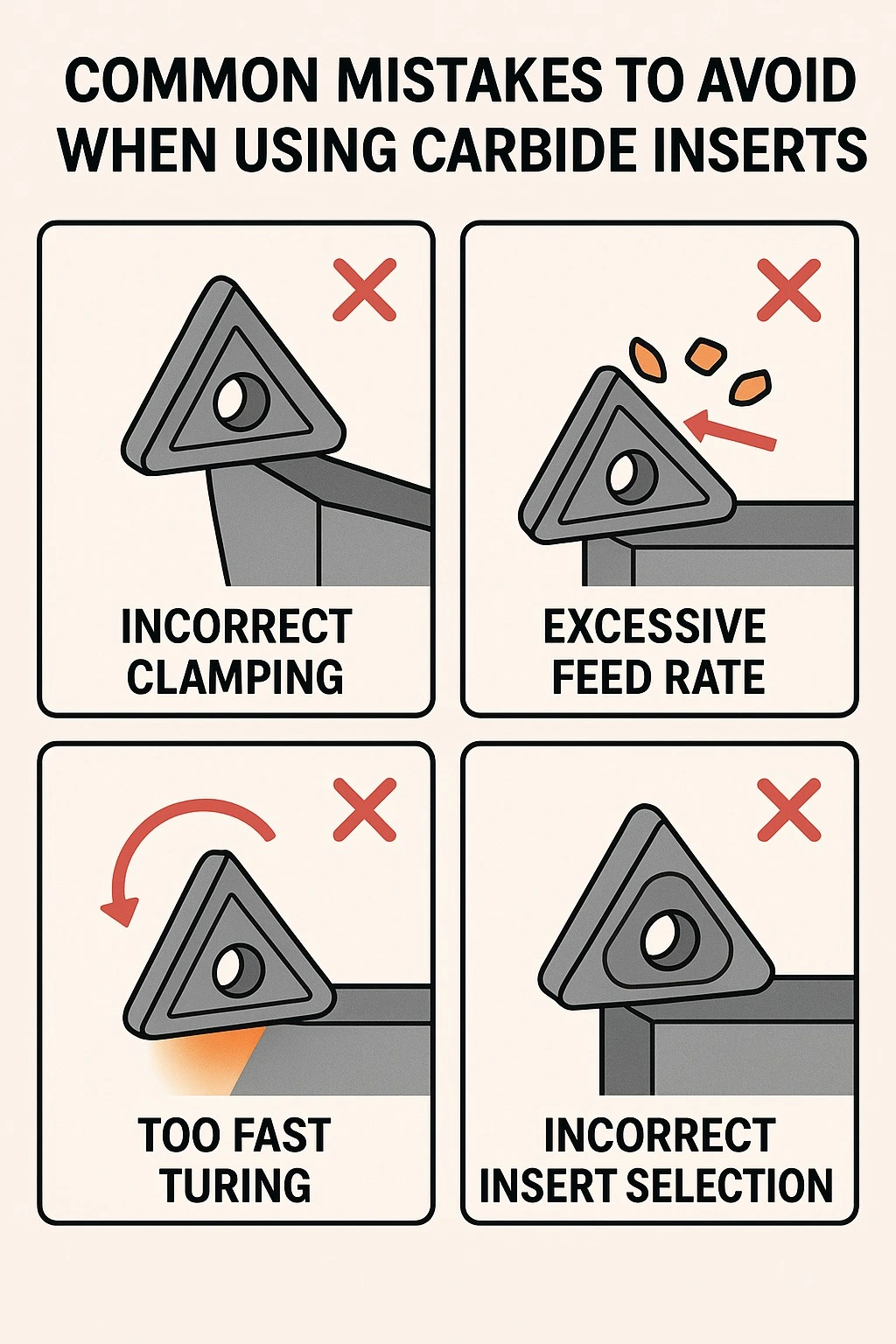

Common Mistakes to Avoid When Using Carbide Inserts

Carbide inserts are the backbone of modern CNC cutting tools — they deliver high metal-removal rates, repeatable surface finish, and long tool life when used correctly. But small mistakes in sel...

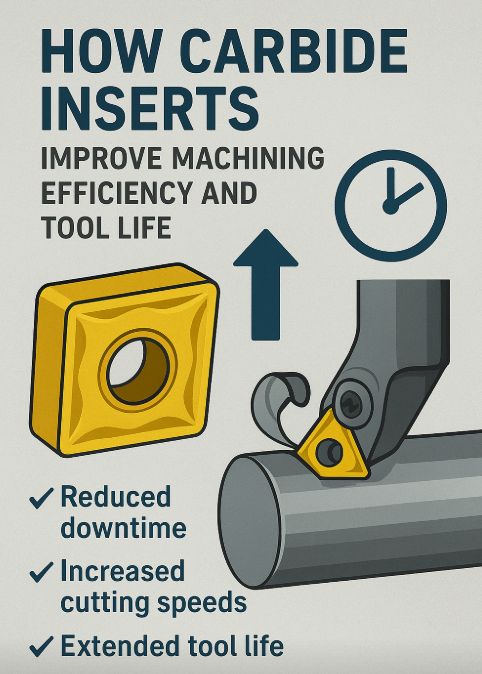

How Carbide Inserts Improve Machining Efficiency and Tool Li...

n modern CNC cutting tools, carbide inserts are the unsung heroes that keep production moving: they reduce downtime, cut cycle time, improve surface finish, and — when selected correctly —...

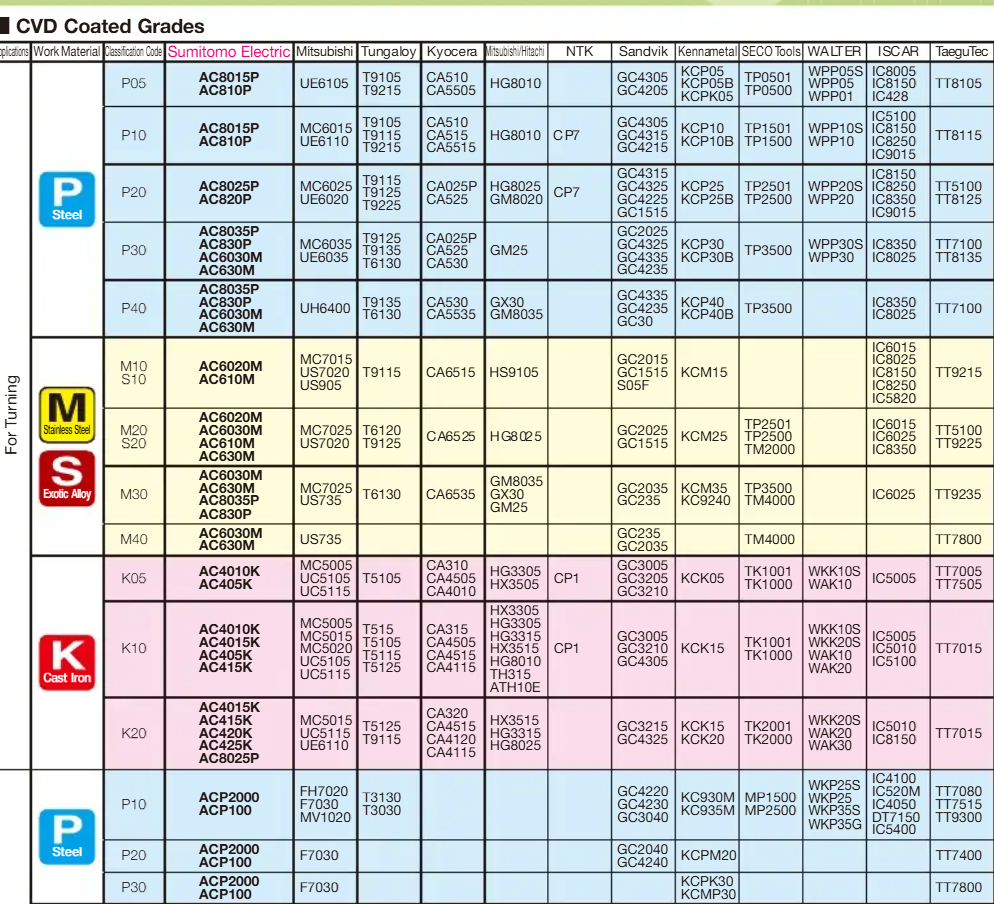

Understanding Carbide Insert Grades and Their Uses

In the fast-paced world of CNC machining and metalworking, selecting the right carbide insert can make the difference between precision and costly errors. Carbide inserts are at the heart of modern ma...

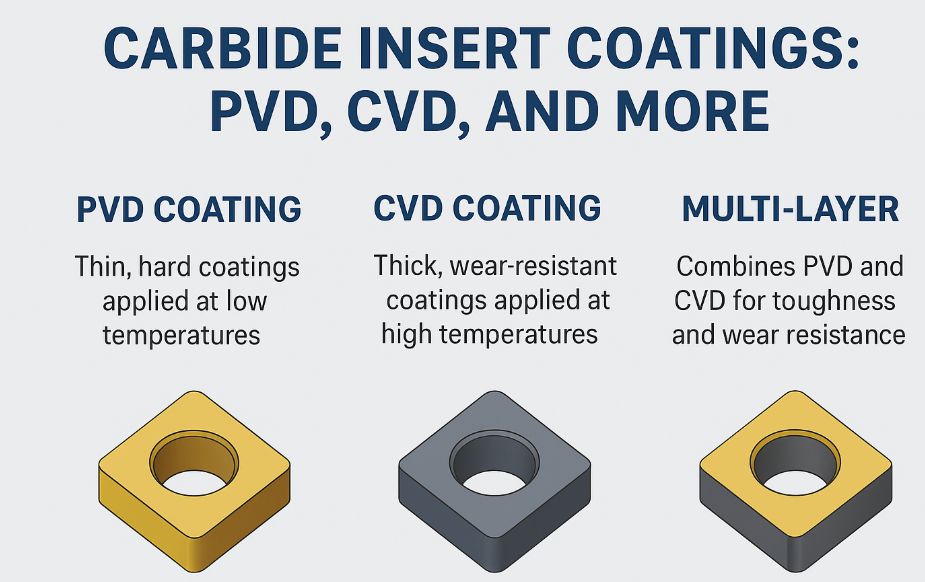

A Guide to Carbide Insert Coatings: PVD, CVD, and More

In the world of CNC machining, the performance of carbide inserts can make or break productivity. One of the most critical factors influencing tool life, cutting efficiency, and surface finish is the...

Carbide Inserts vs. HSS Tools: Which One Should You Use?

Choosing between carbide inserts and HSS (high-speed steel) tools is one of the most common — and impactful — decisions in CNC machining. The right choice affects cycle time, surface finis...

How to Select the Right Carbide Insert for CNC Machining

Choosing the right carbide inserts is one of the highest-leverage decisions in CNC machining. The correct insert reduces cycle time, improves surface finish, lowers tooling cost per part, and prevents...