Latest Blogs

ISO Carbide Insert Nomenclature Explained (With Examples)

Carbide inserts are the replaceable cutting tips that make modern CNC turning and milling fast, repeatable and cost-effective. Reading the ISO insert code lets you order the exact geometry (shape, rel...

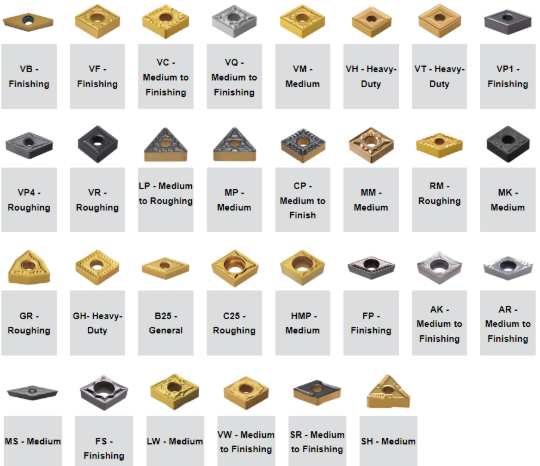

Different Types of Carbide Inserts and Their Applications

Carbide inserts are the replaceable cutting edges at the heart of modern CNC cutting tools. They let manufacturers change geometry, material grade and coatings without regrinding a whole tool —...

What Are Carbide Inserts? A Complete Beginner’s Guide

Carbide inserts are the tiny, replaceable cutting tips that do the heavy lifting in metal cutting. They sit in a toolholder on a CNC lathe or mill, shear metal at incredible speeds, and can be rotated...

Kyocera vs. TaeguTec: An In-Depth Comparison of Carbide Inse...

Carbide inserts are critical components in CNC machining, affecting efficiency, precision, and tool life. Among the top manufacturers, Kyocera and TaeguTec stand out for their innovative cutting tools...

Guide to Selecting the Right Carbide Inserts for Your CNC Ma...

Selecting the right carbide inserts for your CNC machine is essential to achieving optimal cutting performance, reducing costs, and ensuring high-quality outputs. This guide will walk you through the...

U Drills: Uses, Diagram, Brands and Applications

U-drills (commonly called indexable insert drills or “U-type” drills) are high-productivity CNC cutting tools for efficient holemaking. Unlike solid-carbide twist drills, U-drills use repl...

Feeler Gauge: Uses, Diagram, Brands and Applications

The tiny tool that protects your expensive tooling In precision machining, the smallest gaps can cause the biggest headaches—chatter, poor surface finish, tolerance drift, even chipped carbide...