Latest Blogs

Signs Your Carbide Insert Needs Replacement

Knowing when to replace a carbide insert is crucial for maintaining accuracy, productivity, and cost efficiency in CNC machining. Worn inserts can cause poor surface finish, dimensional errors, vibrat...

Proper Storage and Handling of Carbide Inserts

Proper storage and handling of carbide inserts are critical to achieving consistent performance and reducing tooling costs in CNC machining. Carbide inserts, whether for turning, milling, or drilling,...

Coolants and Carbide Inserts: Best Practices for Longevity

Coolant application is one of the most critical — yet often overlooked — factors in extending the life of carbide inserts. From flood and high-pressure coolant (HPC) to thru-tool, MQL, and...

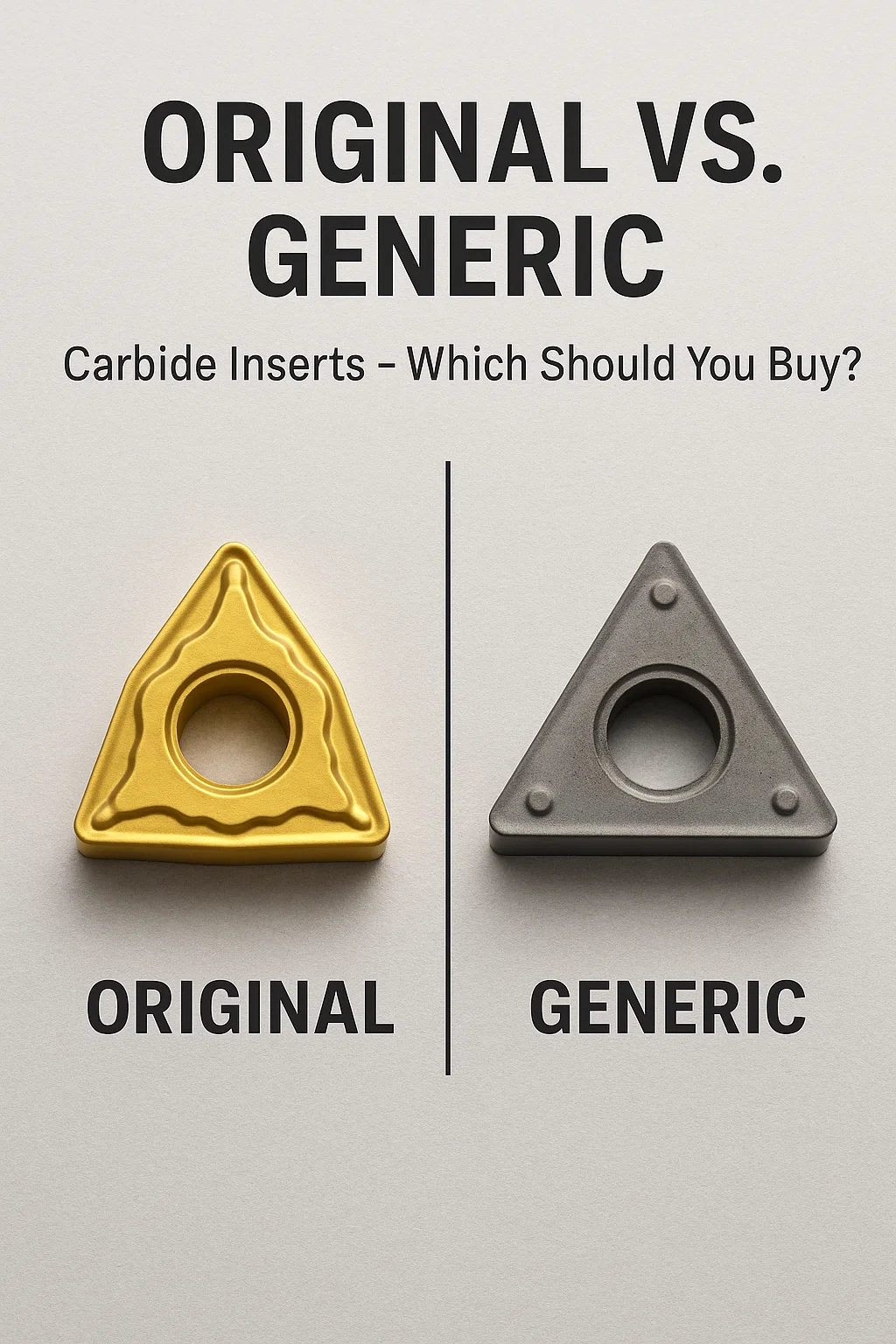

Original vs. Generic Carbide Inserts – Which Should You Buy?

Choosing between original and generic carbide inserts is a crucial decision for machinists and manufacturers. Original inserts from brands like Sandvik, Kennametal, Mitsubishi, ISCAR, and Widia offer...

Top Carbide Insert Brands Compared: Sandvik, Kennametal, Mit...

Carbide inserts are the backbone of modern CNC machining, ensuring precision, productivity, and cost efficiency. But with so many leading brands — Sandvik, Kennametal, Mitsubishi, ISCAR, Widia,...

Cutting Speeds And Feeds for Carbide Inserts: A Practical Gu...

Cutting Speeds and Feeds for Carbide Inserts: A Practical Guide is a hands-on resource for machinists, shop supervisors, and process engineers who want predictable results from carbide tooling. Writte...

Carbide Inserts for Heavy-Duty Machining Applications

Heavy-duty machining requires carbide inserts built to withstand extreme cutting forces, heat, and interrupted cuts. This in-depth guide from CNC Tools Depot explains how to select the right ISO 1832-...

How to Extend the Life of Your Carbide Inserts

Maximizing the life of your carbide inserts is key to reducing tooling costs and improving machining efficiency. This guide from CNC Tools Depot — the world’s largest marketplace for CNC c...

High-Performance Carbide Inserts for Cast Iron Machining

Machining cast iron requires carbide inserts designed to handle abrasive wear, graphite microstructures, and chip-breaking behavior. This expert guide from CNC Tools Depot explains how to select high-...