Best Carbide Inserts for Stainless Steel Machining

Discover the best carbide inserts for stainless steel machining. Learn how ISO insert nomenclature, coatings, chipbreakers, and top brands like Sandvik, Kennametal, and Iscar improve tool life, chip control, and surface finish.

Stainless steel is everywhere — medical implants, automotive components, aerospace parts and food-grade fittings — and it’s notoriously fussy to cut. Choosing the right carbide inserts and the correct ISO insert nomenclature lets you turn that difficulty into consistent parts, longer tool life and lower cost-per-part. This guide explains, step-by-step, how to pick and use the best CNC cutting tools (turning inserts and milling inserts) for stainless steel — with clear ISO 1832 decoding, brand-typical recommendations, and practical shop advice.

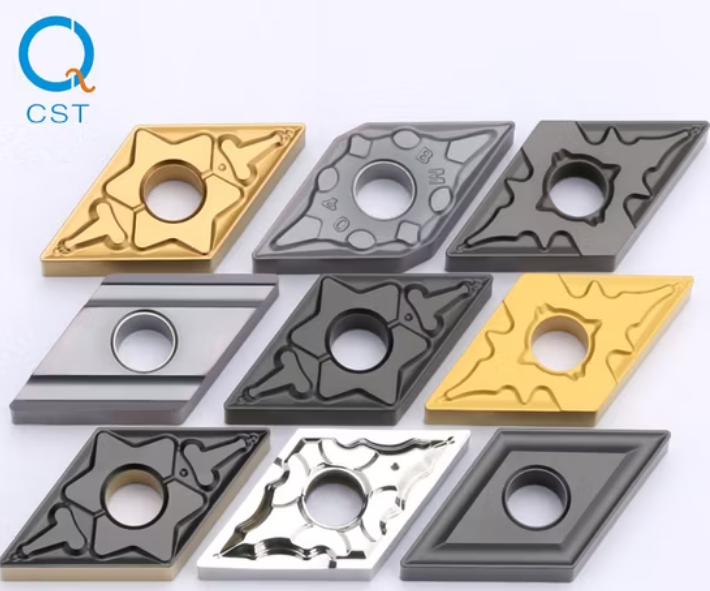

What Are Carbide Inserts?

Carbide inserts are replaceable cutting tips made from tungsten carbide with a cobalt binder. They are widely used in CNC cutting tools, offering high hardness, wear resistance, and thermal stability for demanding operations.

Unlike HSS (High-Speed Steel), carbide inserts maintain sharpness at high temperatures, making them ideal for stainless steel machining, which generates significant heat.

ISO Insert Nomenclature Simplified

Understanding ISO insert codes ensures you pick the right geometry and coating for the job. For example, consider the insert code:

CNMG 120408

- C – Insert shape: 80° diamond

- N – Clearance angle: 0° (neutral)

- M – Tolerance: Medium

- G – Ground insert (precision finish)

- 12 – Inscribed circle (mm)

- 04 – Thickness (mm)

- 08 – Cutting edge length (mm)

Other important ISO features include:

- Chip breaker designation – Controls chip formation and evacuation.

- Coating type – PVD or CVD coatings improve wear resistance and reduce built-up edge (BUE).

Key Features for Stainless Steel Inserts

When machining stainless steel, consider the following:

Coating

- PVD (Physical Vapor Deposition): Thin, hard coatings like TiAlN improve wear resistance and prevent sticking.

- CVD (Chemical Vapor Deposition): Thicker coatings for heavy-duty operations, better for high-speed roughing.

Geometry & Chip Breakers

- Positive rake angles reduce cutting forces, ideal for soft stainless steels like 304 and 316.

- Special chip breaker designs ensure continuous, controllable chips, preventing jamming in CNC lathes and mills.

Clearance Angle & Tolerance

- 0° to 7° clearance is common for stainless steel. Too high a clearance can weaken the edge.

- Medium tolerance (M) is standard for general operations; tight tolerance (H) is used for precision applications.

Edge Preparation

- Honing or micro-edge chamfering prevents chipping in tough, fibrous stainless steel.

Best Carbide Inserts for Stainless Steel: Brand Comparison

| Brand | Popular Inserts | Coating | Recommended Use |

|---|---|---|---|

| Sandvik | CNMG120408-SM | TiAlN, PVD | Precision turning, automotive components |

| Kennametal | WNMG080408-KC | PVD, CVD | General machining, aerospace parts |

| Iscar | CNMG120404-HA | TiCN / Al2O3 | Roughing & finishing stainless steel |

| Kyocera | VNMG160404-VQ | PVD TiAlN | High-feed turning applications |

| Korloy | CNMG120408-HA | PVD | Mold & die work, thin-wall components |

Practical Applications

- Automotive: Exhaust components, engine blocks, turbochargers.

- Aerospace: Stainless steel landing gear and hydraulic components.

- Die & Mold: Complex stainless dies, molds, and fixtures.

- General Machining: Shafts, fasteners, structural components.

Step-by-Step Guide to Choosing Inserts for Stainless Steel

-

Identify stainless steel grade (304, 316, 17-4 PH, etc.).

-

Select insert geometry – Positive rake for soft grades, neutral for harder ones.

-

Choose coating – PVD for finishing, CVD for roughing.

-

Check ISO code – Confirm shape, clearance, tolerance, and chip breaker.

-

Test in CNC machine – Adjust feeds and speeds for optimum surface finish.

Frequently Asked Questions

Short: CNMG is an ISO-style insert code. C = 80° diamond shape, N = 0° clearance (neutral), M = medium tolerance, G (or following letter) indicates cross-section/type. The numbers after (e.g., 120408) tell you size, thickness and nose radius. Always confirm suffixes with the vendor.

There’s no single “best” insert — preferred solutions are stainless-specific grades (PVD/CVD combinations) with chipbreakers and polished edges. Sandvik’s GC2220, Kennametal XPLT grades and Iscar stainless grades are solid starting points; pick by trial for your alloy and machine

Read left to right: shape → clearance angle → tolerance → cross-section/type → size (IC) → thickness → nose radius → optional chipbreaker/grade suffix. Use the manufacturer catalog to translate suffixes. Walter and ISO 1832 charts make this quick.

CVD coatings are typically thicker and provide strong wear/thermal resistance (good for roughing and high speeds); PVD coatings are thinner and let you keep a sharper edge (good for finishing and reducing BUE). Many modern grades combine the best traits

CNC Tools Depot aggregates leading brands (Sandvik, Kennametal, Iscar, Sumitomo, etc.), provides ISO code filters, chipbreaker/grade cross references, and lets you compare parts and prices side-by-side so you test quickly and buy the right insert for stainless applications.