How to Select the Right Carbide Insert for CNC Machining

Learn how to select the right carbide insert for CNC machining with this expert guide. Understand ISO insert nomenclature, coatings, chipbreakers, and practical applications to boost tool life, accuracy, and efficiency.

Choosing the right carbide inserts is one of the highest-leverage decisions in CNC machining. The correct insert reduces cycle time, improves surface finish, lowers tooling cost per part, and prevents scrapped parts. Yet the alphanumeric ISO codes, dozens of chipbreakers and multiple coating types make selection look intimidating. This guide breaks it down step-by-step using the ISO standard (ISO 1832) and manufacturer best practices so you can choose with confidence

Introduction

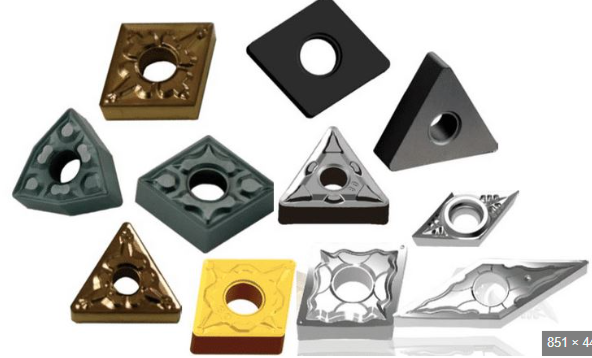

Understanding Carbide Inserts

Carbide inserts are replaceable cutting tips made of tungsten carbide, often coated to improve wear resistance and reduce friction. They are widely used in CNC cutting tools for turning, milling, grooving, and threading operations.

Key Advantages:

- High hardness for cutting tough materials

- Heat resistance for high-speed operations

- Precision and consistency with repeatable geometry

- Cost-effective by reducing tool replacement frequency

Reading ISO Carbide Insert Nomenclature

ISO 1832 defines a standard code to describe inserts. Let’s break down an example:

Example: CNMG 120408

- C = 80° Diamond shape (insert geometry)

- N = 0° Clearance angle (relief angle of the insert)

- M = Medium tolerance (accuracy level)

- G = Ground insert (finished for precise fit)

- 12 = Insert size (inscribed circle in mm)

- 04 = Insert thickness (in mm)

- 08 = Nose radius (in mm)

Why ISO Codes Matter

ISO codes allow engineers and operators to quickly identify the right insert for the job, ensuring compatibility with the holder, machining operation, and material type.

Factors to Consider When Selecting a Carbide Insert

Material of Workpiece

- Steel: PVD-coated inserts (TiN or TiAlN) often work best.

- Stainless Steel: Use tougher grades like K or M, with sharp cutting edges to reduce built-up edge.

- Cast Iron: CVD coatings with strong cutting edges are ideal.

- Non-ferrous Metals: Uncoated or light PVD coating inserts to prevent material sticking.

Type of Operation

- Turning Inserts: For cylindrical shapes, with precise nose radius for surface finish.

- Milling Inserts: Often indexable with multi-edge geometry to handle high feed rates.

- Grooving/Parting Inserts: Require specific widths and chip breaker designs.

Insert Geometry & Chip Breakers

- Geometry: Influences cutting forces, tool life, and surface finish.

- Chip Breakers: Control chip flow, prevent tangling, and improve safety. Example: Sandvik’s multi-purpose chip breakers reduce heat in finishing operations.

Coating Selection

- PVD Coating: Thin, hard, ideal for high-speed machining.

- CVD Coating: Thicker, durable, better for roughing and heavy cuts.

- Uncoated Inserts: For non-ferrous metals or low-speed operations.

Brand Considerations

While quality standards are similar, insert performance can slightly vary:

- Sandvik Coromant: Excellent for high-speed steel and stainless steel.

- Kennametal: Offers robust multi-purpose grades.

- Iscar: Known for innovative chip breakers and high-precision inserts.

Practical Applications by Industry

- Automotive: High-speed turning and milling of aluminum and steel components.

- Aerospace: Hard alloys and titanium machining using coated carbide inserts for durability.

- Die & Mold: Precision finishing and grooving with specialized insert shapes.

- General Machining: Cost-effective solutions for steel, cast iron, and non-ferrous metals.

Conclusion

Selecting the right carbide insert is a combination of understanding ISO nomenclature, material compatibility, insert geometry, and coating. Using the correct insert improves machining efficiency, prolongs tool life, and ensures a high-quality surface finish. Explore the wide range of carbide inserts from trusted brands like Sandvik, Kennametal, Iscar, Kyocera, and Mitsubishi at CNC Tools Depot, your go-to marketplace for all CNC tooling needs.

Step-by-Step Selection Guide

-

Identify Workpiece Material → Steel, Stainless, Cast Iron, Aluminum.

-

Choose Operation Type → Turning, Milling, Grooving, Threading.

-

Check ISO Insert Code → Ensure correct shape, clearance, tolerance, and size.

-

Select Coating → PVD, CVD, or uncoated based on material and speed.

-

Evaluate Chip Breaker → For chip control and surface finish.

-

Compare Brands & Grades → Balance performance and cost.

-

Test in Actual Machining → Monitor tool wear and surface finish for optimization.

Frequently Asked Questions

It’s an ISO code: C = 80° diamond, N = 0° clearance, M = medium tolerance, G = ground insert.

CVD-coated inserts with a sharp chip breaker are ideal for heat-resistant stainless steels.

Each letter and number represents shape, clearance, tolerance, chip breaker, and size. Example: CNMG 120408.

CVD is thicker and more durable for roughing; PVD is thinner and better for finishing operations.

We stock all leading brands, provide technical expertise, and ensure verified, high-quality inserts for every CNC application.