Latest Blogs

How to Regrind and Reuse Carbide Inserts (When Possible)

Regrinding and reusing carbide inserts can extend tool life, lower machining costs, and reduce waste — but only when done correctly. This expert guide from CNC Tools Depot explains the technical...

Choosing Carbide Inserts for CNC Lathe Operations

Selecting the correct carbide inserts for CNC lathe operations is essential for achieving precision, surface finish, and cost efficiency. This expert guide from CNC Tools Depot — the world&rsquo...

The Role of Carbide Inserts in Precision Machining

Carbide inserts are the backbone of modern precision machining, enabling tight tolerances, superior surface finishes, and consistent repeatability across industries like aerospace, automotive, die &am...

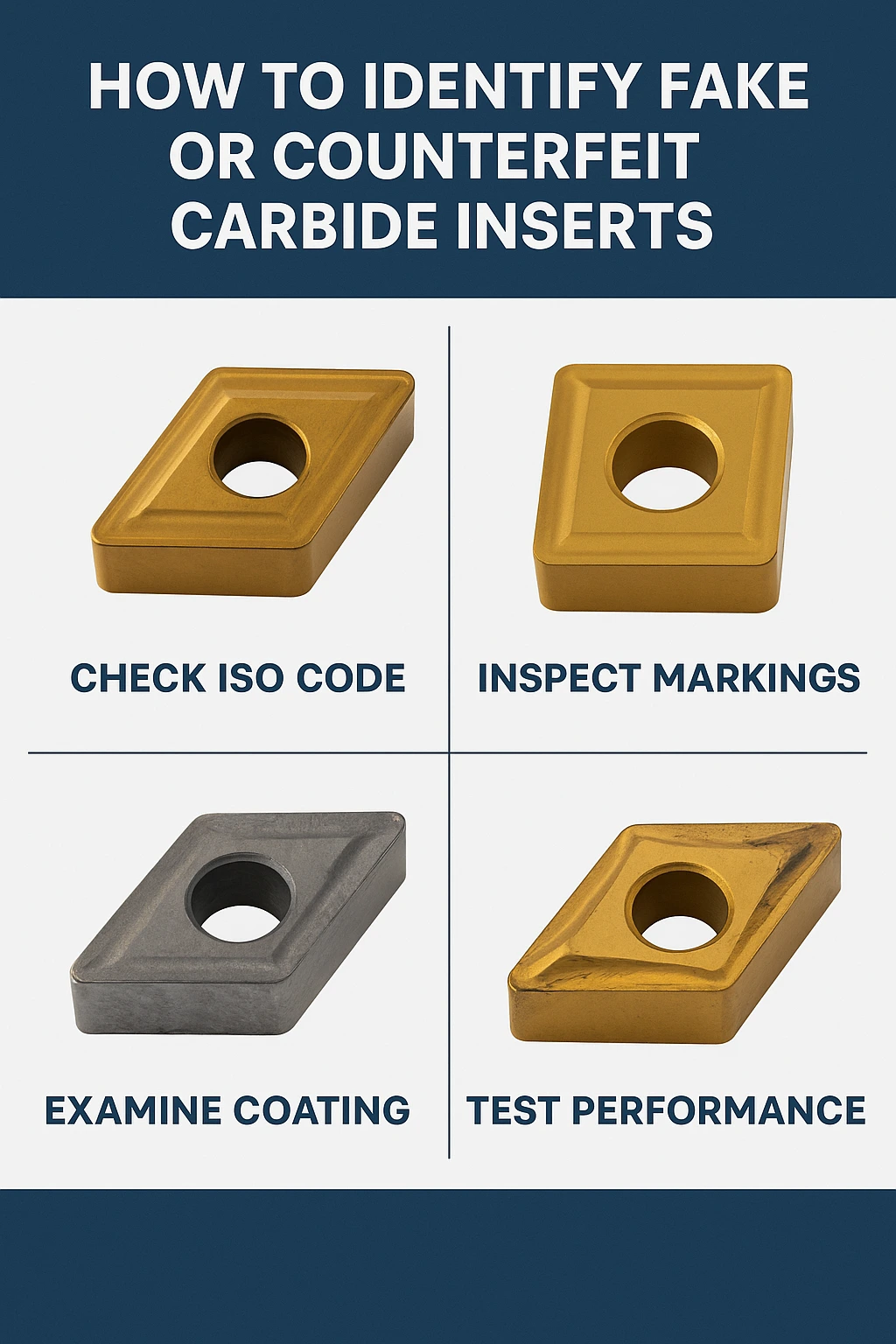

How to Identify Fake or Counterfeit Carbide Inserts

In the world of CNC machining, precision is everything. Whether you are producing automotive components, aerospace parts, or general engineering spares, the smallest deviation in tool geometry can mea...

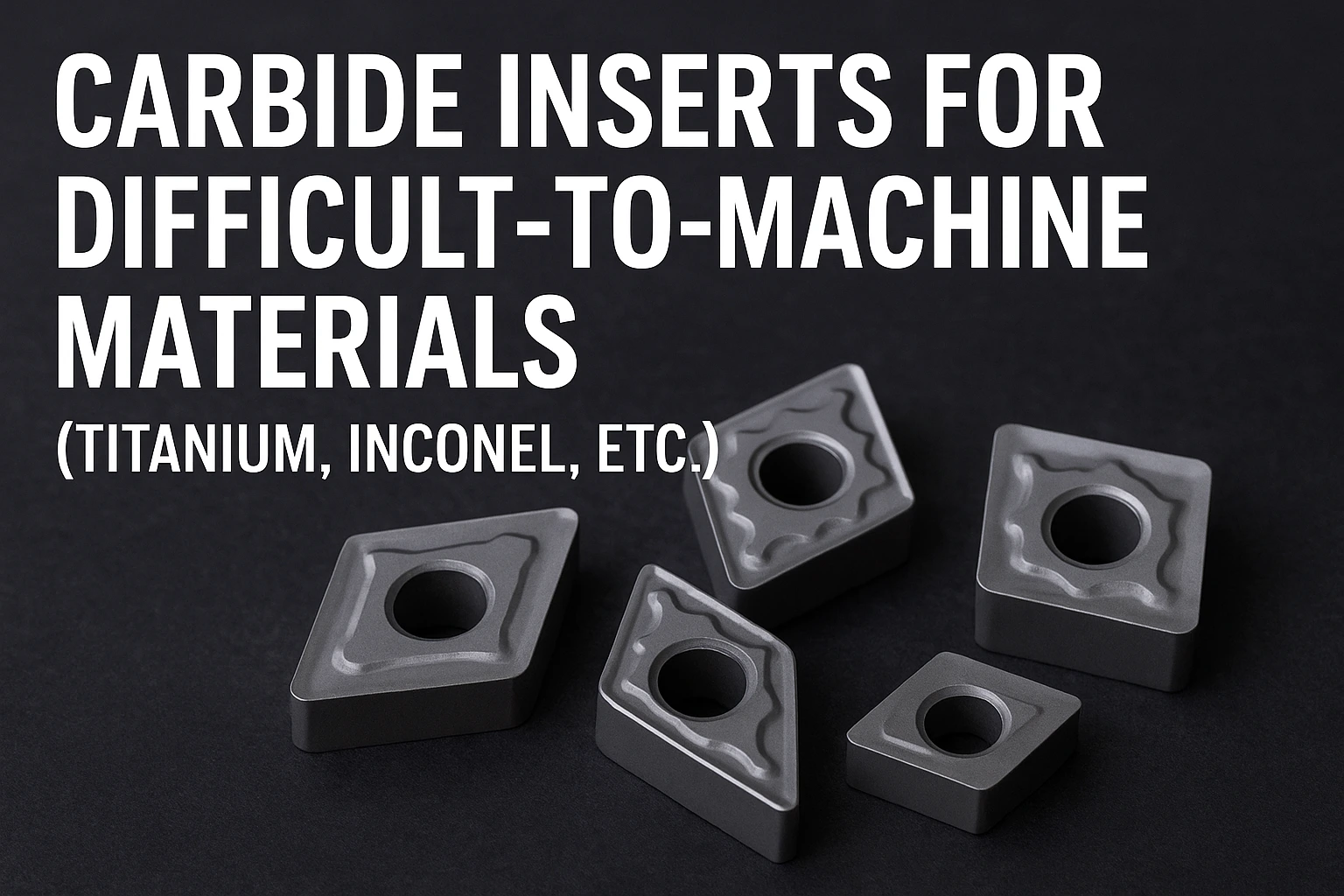

Carbide Inserts for Difficult-to-Machine Materials (Titanium...

Machining titanium, Inconel, and other high-performance alloys presents unique challenges such as rapid tool wear, heat concentration, and work-hardening. This in-depth guide from CNC Tools Depot &mda...

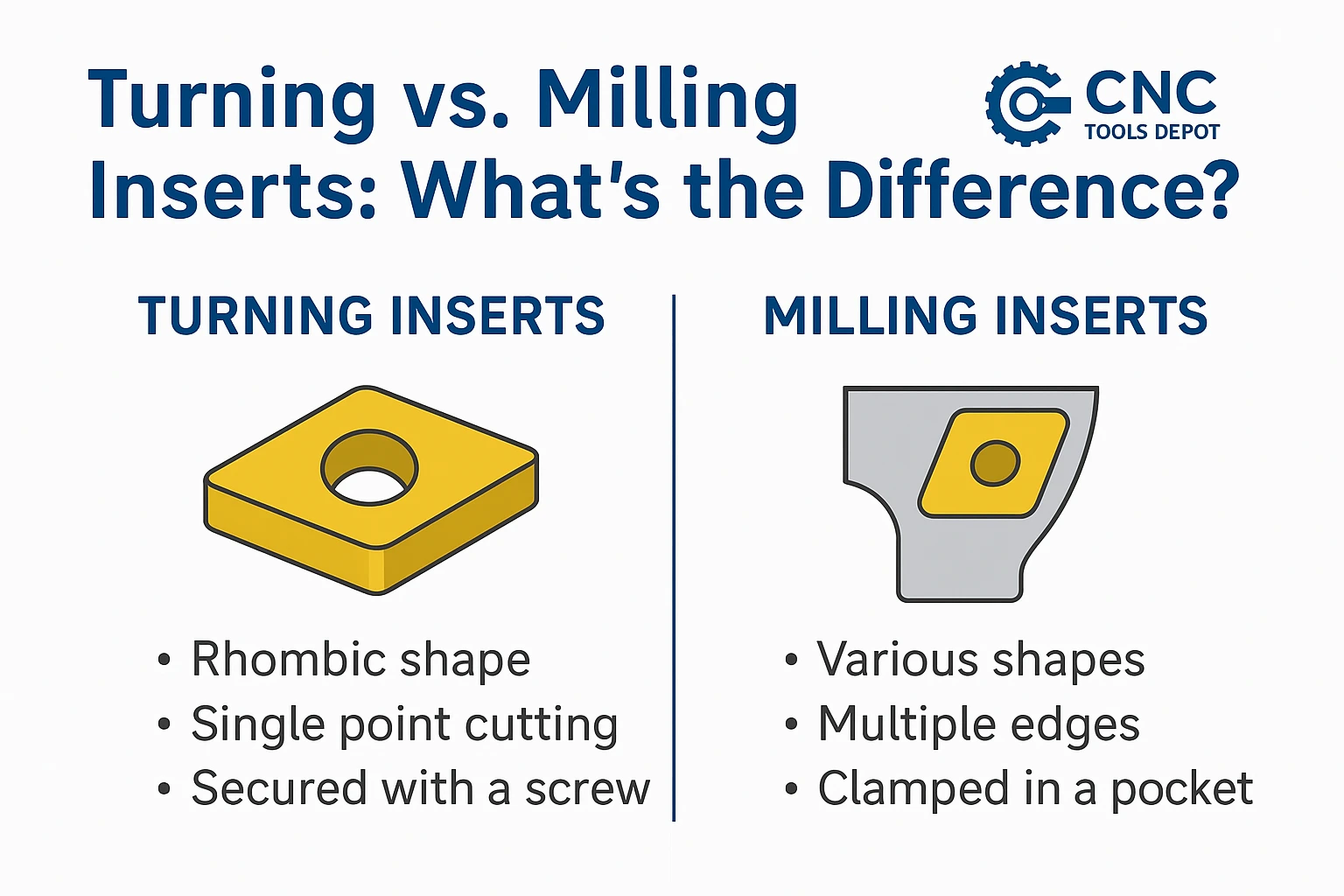

Turning vs. Milling Inserts: What’s the Difference?

Turning inserts, often identified by ISO 1832 codes such as CNMG or DNMG, are optimized for continuous single-point cutting operations on lathes. Their geometry, chipbreaker design, clearance angles,...

How to Reduce Tool Wear with the Right Carbide Insert

CNC Tools Depot is the world’s largest marketplace for carbide inserts, stocking all leading global brands including Sandvik Coromant, Kennametal, Iscar, Korloy, Kyocera, Mitsubishi, Widia, Taeg...

Cost vs. Performance: Are Premium Carbide Inserts Worth It?

CNC shops, contract manufacturers, and in-house production teams constantly balance two pressures: reduce per-part cost and keep quality and uptime high. Carbide inserts are small components that dire...

Carbide Inserts Buying Guide: How to Choose the Right One On...

Carbide inserts are the backbone of modern CNC machining, but selecting the right one online can be confusing. Our Carbide Inserts Buying Guide makes it simple by decoding the ISO 1832 nomenclature&md...