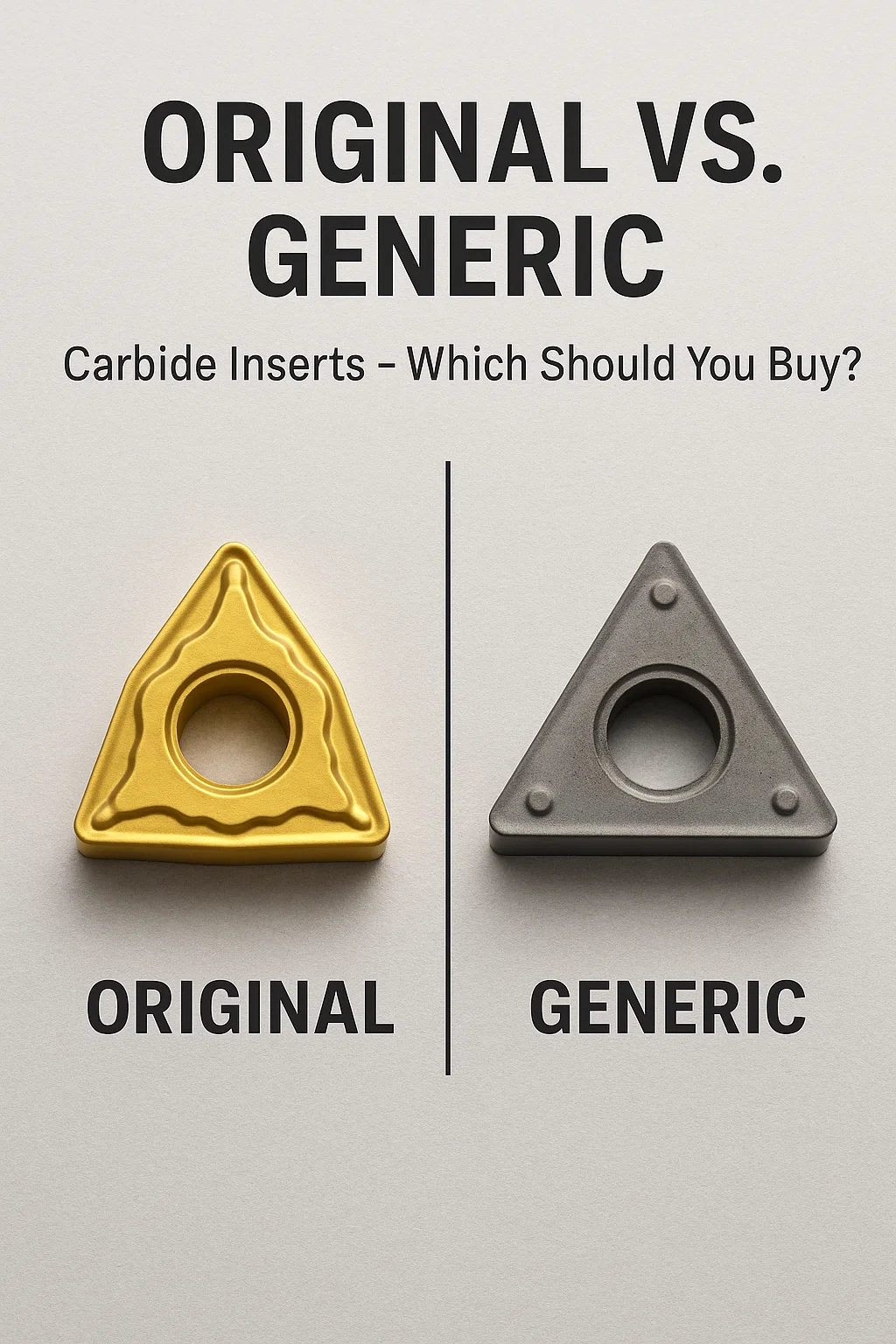

Original vs. Generic Carbide Inserts – Which Should You Buy?

Discover the pros and cons of original vs. generic carbide inserts. Learn differences in ISO codes, coatings, tool life, and cost to choose the right CNC cutting tool.

Choosing between original and generic carbide inserts is a crucial decision for machinists and manufacturers. Original inserts from brands like Sandvik, Kennametal, Mitsubishi, ISCAR, and Widia offer advanced coatings, precise ISO tolerances, and reliable tool life. Generic inserts, while cost-effective, may lack consistency in chipbreaker design, coating quality, and wear resistance. This guide explains ISO 1832 insert nomenclature (e.g., CNMG 120408), compares technical features like coatings and tolerances, and highlights practical applications across industries such as automotive, aerospace, die & mold, and general machining. Whether you prioritize cost savings or performance, CNC Tools Depot helps you choose the right carbide inserts with confidence.

What are carbide inserts?

In modern CNC machining, carbide inserts are the cutting edge that defines tool life, cycle time, and part quality. Every machinist faces the question: Should I invest in original branded inserts from Sandvik, Kennametal, Mitsubishi, ISCAR, or try generic alternatives at a lower price?

Choosing the right insert isn’t just about cost — it’s about precision, reliability, and productivity. This blog compares original vs. generic carbide inserts so you can make an informed decision for your shop.

What are carbide inserts?

Carbide inserts are replaceable cutting tips made from tungsten carbide with cobalt binder. Instead of resharpening tools, operators simply rotate or replace the insert.

For example, a CNMG 120408 insert is an 80° diamond-shaped turning insert. According to ISO 1832:

- C = 80° diamond shape

- N = 0° clearance (negative insert)

- M = medium tolerance

- G = ground insert

- 12 = inscribed circle ≈ 12.7 mm

- 04 = thickness ≈ 4.76 mm

- 08 = nose radius 0.8 mm

This systematic coding ensures compatibility across brands.

ISO 1832

The ISO 1832 standard defines insert codes globally.

- Shape (C, D, S, T, R) = insert profile

- Clearance (N, C, P, etc.) = relief angle for cutting

- Tolerance (M, G, etc.) = dimensional precision

- Size, thickness, nose radius = coded numbers

- Chipbreaker and coating = manufacturer-specific suffixes

Understanding ISO codes helps machinists compare inserts across brands — original or generic.

Original (branded) carbide inserts

Original inserts are manufactured by global leaders like Sandvik Coromant, Kennametal, Mitsubishi, ISCAR, and Widia.

Key features:

- Strict adherence to ISO tolerances

- Advanced CVD/PVD coatings for heat and wear resistance

- Proprietary chipbreaker geometries tuned for specific applications

- Extensive datasheets and machining recommendations

Example: Sandvik’s GC4425 grade uses CVD coating optimized for steel turning, offering longer tool life and predictable wear.

Generic (non-branded) carbide inserts

Generic inserts are produced by smaller or local manufacturers, often at lower cost.

Key features:

- Usually ISO-compatible shapes and sizes

- Lower price point (often 30–50% cheaper)

- Limited technical documentation

- Coating and chipbreaker technology may lag behind top brands

They work well for non-critical operations (light roughing, general machining) but may struggle in demanding aerospace or high-volume automotive applications.

Key differences

| Feature | Original Inserts (Sandvik, Kennametal, etc.) | Generic Inserts |

|---|---|---|

| Tolerance accuracy | High, ISO-certified, repeatable | Varies, looser tolerances |

| Coatings | Advanced CVD/PVD with multi-layer tech | Basic or single-layer |

| Chipbreaker design | Application-specific (finishing, roughing) | Generic designs |

| Tool life | Predictable, longer (20–40% more) | Shorter, inconsistent |

| Datasheets | Detailed parameters, cutting speeds, feeds | Minimal info |

| Cost | Higher upfront | Lower upfront |

Cost vs. performance

Think of inserts like car tires:

- A branded tire offers durability, grip, and warranty.

- A generic tire gets the job done but may wear out faster.

Similarly:

- Original inserts = reliability, longer tool life, predictable results.

- Generic inserts = short-term savings, but may cost more due to downtime, scrap, and faster wear.

Frequently Asked Questions

Yes, most generics follow ISO 1832 for shape, size, and clearance — but tolerances and coatings may differ.

Typically yes. Branded inserts with advanced coatings can last 20–40% longer under identical conditions.

You can, but branded PVD-coated inserts (e.g., Sandvik GC2025, Kennametal KCU25) perform far better in stainless.

It’s an ISO code: C = 80° diamond, N = 0° clearance, M = tolerance, G = ground insert, 12 = size, 04 = thickness, 08 = 0.8 mm nose radius.

Aerospace, die & mold, and high-volume automotive — where tool failure or scrap costs far outweigh insert savings.