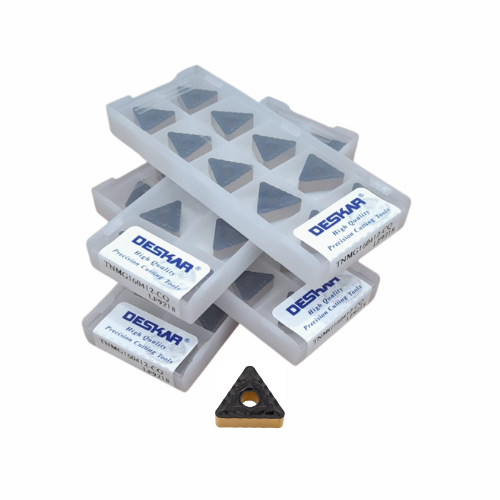

Duracarb TNMG160412 56 DC9025

Duracarb TNMG160412-56 DC9025 – PVD‐coated carbide turning insert with high wear resistance. Six cutting edges, fine corner radius, excels in semi-finishing & finishing steel & stainless. Available now at CNC Tools Depot.

The Duracarb TNMG160412-56 DC9025 is engineered to deliver superior machining performance in steel and stainless steel turning operations. It features the TNMG geometry (60° triangular, negative rake), offering six usable cutting edges for extended usage. The “-56” corner radius gives a fine finish while maintaining strength.

The DC9025 grade is a PVD-coated carbide, designed for excellent wear resistance, heat stability and toughness. This makes it especially effective in semi-finishing to finishing cuts where surface finish and component accuracy are critical.

With a fine corner radius and stable geometry, it controls chip flow well and resists built-up edge, which means fewer tool changes, less downtime, better consistency. Suitable for applications in automotive parts (shafts, housings), aerospace components, dies & moulds, general engineering – especially where steel/stainless are involved.

CNC Tools Depot holds stock across variants. Bulk deals & quick delivery available. Message us or call to get your pricing & shipment lead time.

🔍 Key Features & Specs:

• Shape/Geometry: TNMG – 60° triangular insert, negative‐rake design, six cutting edges.

• Size / Dimensional Spec: “160412-56” – inscribed circle ~16 mm / corner radius ~1.2 mm (common “56” RMS radius) etc.

• Grade / Coating: DC9025, PVD coated carbide – optimized for toughness + wear resistance in steel & stainless steel (grades P15-P35).

• Applications: External turning, semi-finishing to finishing, stable cuts, good chip control.

🏆 Why It’s a Best Seller:

• Less downtime: Six cutting edges means more parts per insert before replacement.

• Better surface finish: Fine corner radius + negative geometry reduce vibration and built-up edge.

• High wear resistance: DC9025’s coating holds up under heat & abrasion, extending life.

• Cost efficiency: Fewer insert changes, less reject / rework.

🏭 Application Industries:

Automotive, aerospace components, die & mold work, general engineering, stainless steel fabrications.

Related Products

You May Also Like

Frequently Asked Questions

It is optimized for steel and stainless steel (typically P-class steels), performing well in semi‐finishing and finishing operations.

The “56” denotes a specific corner radius (often ~1.2 mm in the “56” variant), which balances between strength (for edge life) and ability to produce fine surface finish.

It’s not designed for heavy roughing or extremely interrupted cuts. Its strength lies in semi-finishing / finishing where stable cutting, good surface finish and tool life matter. For roughing, a tougher grade or larger corner radius may be wiser.

There are six usable cutting edges per insert. That means when one edge wears out, you rotate to the next; reduces cost per component, lowers tool change time, improves productivity.

You can DM, WhatsApp, or call CNC Tools Depot. Tell us length, quantity, required delivery. We’ll send you stock status, price (and any bulk discount) plus expected delivery.