Login / Register

Verify OTP

Update Profile

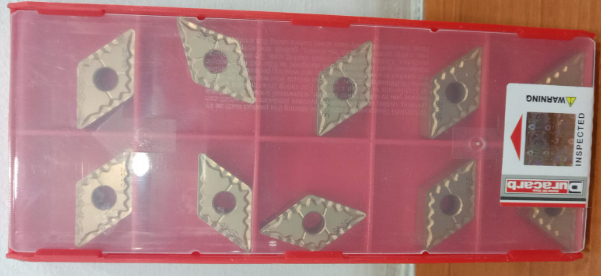

Duracarb VNMG160404 41 DP5010

Elevate your machining efficiency with the Duracarb VNMG160404 41 DP5010 carbide insert. Designed for high-speed turning, it offers superior wear resistance and a fine surface finish, making it ideal for industries like automotive, aerospace, and general engineering.

The Duracarb VNMG160404 41 DP5010 carbide insert is engineered for high-speed turning operations, offering exceptional wear resistance and a fine surface finish. With its 35° diamond shape and 0.4 mm corner radius, it ensures precise cuts and minimal tool wea

Key Features & Specifications:

Key Features & Specifications:

-

Geometry: 35° diamond shape

-

Insert Thickness (S): 4.76 mm

-

Inscribed Circle Diameter (IC): 9.52 mm

-

Corner Radius (RE): 0.4 mm

-

Grade: DP5010

-

Recommended Cutting Conditions: Feed rate: 0.05 - 0.30 mm/rev; Depth of Cut: 0.5 - 2.0 mm

Why It’s a Best Seller:

Why It’s a Best Seller:

The DP5010 grade is renowned for its high wear resistance and ability to maintain a fine surface finish, even under high-speed machining conditions. This makes it a preferred choice for industries requiring precision and durability.

Application

Application Industries:

-

Automotive: Engine components, transmission parts

-

Aerospace: Aircraft structural components, turbine blades

-

General Engineering: Precision shafts, hydraulic components

Frequently Asked Questions

The DP5010 grade is versatile and can handle a wide range of materials, including steels and cast irons, making it ideal for various turning applications.

Yes, the DP5010 grade is designed to perform well in both roughing and finishing operations, providing consistent results across different machining stages.

The recommended feed rate ranges from 0.05 to 0.30 mm/rev, depending on the specific machining conditions and material being processed.

The 35° diamond shape offers improved chip control and stability during high-speed turning, leading to better surface finishes and extended tool life.

Yes, this insert is designed to be compatible with standard CNC turning machines that support the VNMG insert type, ensuring broad applicability across different setups.

© 2026. All Rights Reserved

Disclaimer: All Brand Logos belong to their respective owners, CNC Tools Depot is sharing publicly available information