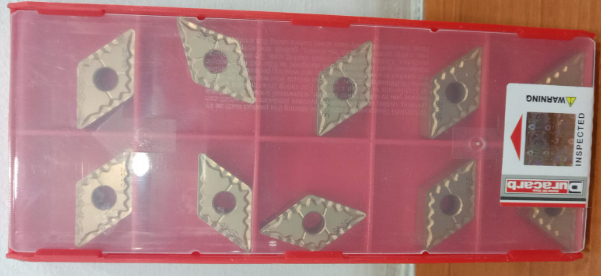

Duracarb VNMG12T304 D2 DP5010

Maximise productivity and surface finish with the Duracarb VNMG12T304 D2 DP5010 – a premium turning insert featuring DP5010 grade carbide, optimised geometry for finishing & profiling, and exceptional wear resistance. Perfect for industries demanding tight tolerances like automotive, aerospace & die & mold.

Unlock high performance in turning operations with the Duracarb VNMG12T304 D2 DP5010, one of our best-selling carbide inserts. Designed to reduce cost per part by increasing tool life and improving surface quality, this insert delivers consistent results even under demanding conditions.

Key Features & Specifications

-

Shape & Geometry: VNMG 12T304 – 55° diamond (acute) shape, negative or neutral relief depending on holder, corner radius approx. 0.4 mm (for fine finishing) — enabling precise profiling, contouring and fine external turning.

-

Grade & Coating: Grade DP5010 from Duracarb. This is a high wear-resistance carbide grade, suited for steel, alloy steels, and stainless applications. The DP-series (especially DP5010) is known for combining toughness & wear resistance.

-

Applications: Best used for precision turning, finishing, light profiling in steel and stainless steel, including alloyed steels up to moderate hardness. Particularly good when surface finish and tolerance are critical.

-

Compatibility: Fits standard VNMG holders; double-sided insert (4 edges) gives economy. Works in external turning, internal profiling, and light turning where finish & dimensional accuracy matter.

Why It’s a Best Seller

-

Longer tool life & less downtime: DP5010’s wear resistance means fewer insert changes, less grinding or scrap, and more continuous production time.

-

Better surface finish: The VNMG geometry plus sharp corner radius gives excellent finishes, letting you meet tighter tolerances without extra passes.

-

High wear & heat resistance: Handles the thermal/stress cycle when cutting steel/stainless steel; reduces edge chipping or crater wear.

-

Cost efficiency: More usable edges per insert, reduced rejects, fewer tool-holder/socket issues.

Industries that Benefit Most

-

Automotive (shafts, axles, engine blocks, gear components)

-

Aerospace (structural components, airfoil profiles, high alloy steels)

-

Die & Mold (fine profile turning, mirror finish)

-

General Engineering & Heavy Machinery (shafts, couplings, precision turned components)

CALL -TO-ACTION

You May Also Like

Frequently Asked Questions

It’s excellent for steel, alloyed steel, stainless steel. Works well in finish profiling and where good surface finish is needed.

About 0.4 mm (T3.04 in the 12T304 designation). This gives a sharper edge for finishing but still enough strength to avoid chipping if feeds are moderate.

Four usable edges (double-sided, two edges per side). Proper indexing/resurfacing yields better cost efficiency.

DP5010 is a high wear-resistance carbide grade (Duracarb’s DP line), designed to handle heat, abrasion and maintain edge integrity. Coating or chipbreaker options further enhance performance in specific conditions.

-

-

Use fine feeds when finishing to protect edge.

-

Moderate depth of cut with rigid tool setup.

-

Use adequate coolant or lubrication to reduce heat.

-

Avoid over-speeding which may increase wear/chipping.

-