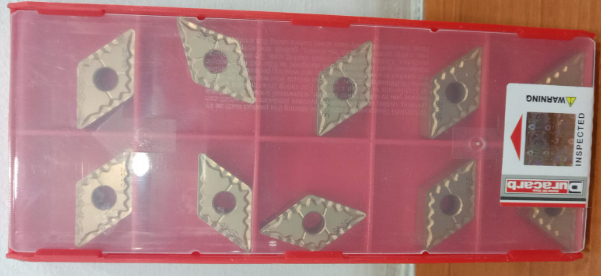

Duracarb TNMG130408 M3 DP5010

Supercharge your turning operations: the Duracarb TNMG130408 M3 insert in DP5010 grade delivers low cutting force, remarkable wear resistance, and consistent finishes in steel and stainless. #CarbideInserts #CNCmachining

Experience precision, durability, and cost-efficiency with the Duracarb TNMG130408 M3 DP5010 carbide turning insert — engineered for superior performance in medium to semi-finishing operations on steel and stainless steel. Built with Duracarb’s advanced coating technology and optimized chipbreaker geometry, this insert delivers stable, consistent performance even under demanding machining conditions.

Hook / Attention Line

Cut more, change less — slash your cost per component with Duracarb TNMG130408 M3 DP5010: longer life, cleaner finish, fewer tool changes.

Key Features & Specs

-

Geometry & type: TNMG 130408 — negative 80° rhombic insert, 7.94 mm inscribed circle, 4.76 mm thickness, corner radius 0.8 mm under M3 chipbreaker designation

-

Grade & coating: DP5010 — a balanced grade in Duracarb’s “Smart / DP / DC” series for steel & stainless applications

-

Cutting applications: Designed for medium and semi-finishing operations in turning, also performs well under interrupted cuts; excellent chip control in low feed and moderate depth conditions

Why It’s a Best Seller

-

Less downtime: thanks to durable wear resistance and stable edge retention, operators spend less time changing inserts

-

Better surface finish: the M3 geometry helps reduce built-up edge and maintain consistent finishes on steels and stainless materials

-

High wear resistance: DP5010 balances toughness and wear life for use in general to slightly aggressive conditions

-

Versatility in interrupted & continuous cuts: maintains stability even under less-than-ideal cutting conditions

🏭 Application Industries

Perfect for shops and production floors in automotive, aerospace, die & mold, general engineering, oil & gas, and heavy machinery where steel and stainless turning is common.

📞 Call-to-Action

You May Also Like

Frequently Asked Questions

It excels in machining steels and stainless steels in medium to semi-finishing turns. The M3 chipbreaker supports stable chip control in those materials.

Yes — though primarily for medium / semi finishing, the DP5010 grade and geometry are robust enough for light interrupted cuts and moderate roughing in stable setups.

The insert is TNMG 130408 (7.94 mm inscribed circle, 4.76 mm thickness) with 0.8 mm corner radius for general-purpose turning.

Thanks to strong edge stability and wear resistance, you don’t need to change inserts as often. That means less machine stoppage, fewer manual interventions, and lower tooling cost per component.

Simply DM us, WhatsApp or call CNC Tools Depot. We’ll confirm real-time stock, share your best bulk pricing, and help you place the order.