Login / Register

Verify OTP

Update Profile

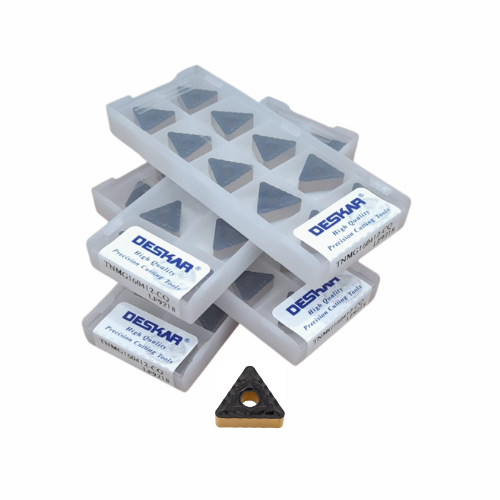

Kyocera TNMG160412CQ CJ225P

The TNMG 160412 CQ CJ225P is a premium Kyocera carbide negative turning insert: CQ chipbreaker for excellent chip control, CJ225P grade CVD-coated for high wear resistance & thermal stability. Best for finishing & medium steel turning where smooth surface and longer tool life matter.

Maximise productivity & minimise downtime with the Kyocera TNMG 160412 CQ CJ225P — one of the best-selling carbide turning inserts for steel machining in India.

Key Features

Key Features & Specs

-

Insert Geometry: TNMG 160412 – 80° rhombic negative, 6 cutting edges for cost efficiency.

-

Chipbreaker: CQ – engineered for smooth chip evacuation in finishing & medium steel turning.

-

Grade: CJ225P – CVD-coated carbide for outstanding wear resistance & thermal stability.

-

Applications: Optimized for finishing/medium cuts in steels and alloy steels.

Why It’s a Best-Seller

Why It’s a Best Seller

-

Longer Tool Life: CJ225P coating withstands heat & abrasion for consistent runs.

-

Better Surface Finish: CQ chipbreaker reduces vibration & ensures smooth chip flow.

-

Lower Cost per Part: Six cutting edges + reduced downtime = more parts per insert.

-

Reliable Performance: Stable cutting even at higher speeds in steels & alloys.

Application

Application Industries

-

Automotive (shafts, hubs, engine components)

-

Aerospace (precision steel parts)

-

Die & Mold (finishing operations on mold steels)

-

General Engineering (production & maintenance machining)

Frequently Asked Questions

It’s designed for finishing to medium turning operations in steels and alloy steels, delivering excellent chip control and long tool life.

The CQ chipbreaker is engineered for stable chip formation, reduced vibration, and improved surface finish in light to medium cutting.

CJ225P is a CVD-coated carbide grade with superior wear resistance, heat stability, and toughness, ideal for steel turning at higher speeds.

Being a TNMG negative triangular insert, it offers six usable cutting edges for maximum economy.

Automotive, aerospace, die & mold, and general engineering industries rely on it for precision steel turning with reduced downtime and higher output.

© 2026. All Rights Reserved

Disclaimer: All Brand Logos belong to their respective owners, CNC Tools Depot is sharing publicly available information