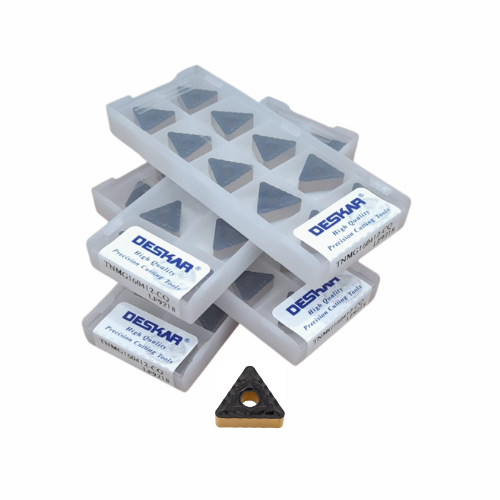

Duracarb TNMG160412 45 DC9025

The Duracarb TNMG160412 45 DC9025 turning insert delivers high wear resistance, enhanced chip control and cost-efficient performance on steel and stainless operations. Available for immediate bulk order at CNC Tools Depot.

Achieve longer tool life, smoother finishes, and lower cost-per-component — all with one insert!

The Duracarb TNMG160412 45 DC9025 is a premium-grade turning insert engineered to deliver consistent performance across a wide range of steel and stainless-steel applications. Designed with Duracarb’s advanced coating technology and precision chip-breaker geometry, this insert ensures stability, wear resistance, and reliability even under demanding machining conditions.

Hook / Attention Line

Attention CNC machinists: boost your productivity and cut your tooling cost-per-component with the premium Duracarb turning insert model TNMG 160412 45 DC9025, now available at CNC Tools Depot – India’s largest marketplace for carbide inserts.

Key Features & Specs

-

Geometry: TNMG (triangular negative insert) with 45° lead angle gives excellent chip-flow control and stability in medium to rough turning. According to Duracarb’s catalogue, TNMG 160412 45 is defined for medium & roughing operations.

-

Size / Insert Dimensions: For example, part-type TNMG 160412 45 uses IC = 9.52 mm, thickness S = 4.76 mm and corner radius RE = 1.2 mm.

Grade / Coating: Grade DC9025 – a black-coated PVD carbide grade upgraded for improved high-feed performance (up to 20% higher feed compared with older grades) and enhanced resistance to chipping, especially under intermittent cuts or unstable conditions. -

Application: Designed primarily for turning operations of steel and stainless steels (and broader general engineering materials) under medium-to-roughing conditions, where tool life, chip control and surface finish matter. (Duracarb indicates the TNMG 45 family for medium & roughing)

Why It’s a Best Seller

-

Less downtime: With the DC9025 grade you get higher feed & more stable cutting under interrupted cuts—so fewer insert changes and less machine idle time.

-

Better surface finish: The improved coating and geometry deliver smoother finishes – meaning less rework and higher first-pass yield.

-

High wear resistance: The advanced coating resists abrasion and chipping, giving you more parts per insert and reducing cost per component.

-

One insert, many jobs: The TNMG geometry with DC9025 grade is versatile enough for a wide range of jobs—from general engineering to automotive and aerospace roughing/finishing—making inventory simpler.

-

Trusted brand & availability: Duracarb is known for quality carbide tools (AS9100/ISO9001 certified) and via CNC Tools Depot you get fast access plus support

🏭 Application Industries

-

Automotive & engine components – medium to heavy turning of steel/stainless alloys

-

Aerospace – where consistency, tool life and surface integrity matter

-

Die & mold – where intermittent cuts demand high chipping resistance

-

General engineering – shops machining a variety of steels and requiring a go-to insert for medium/rough turning

Related Products

You May Also Like

Frequently Asked Questions

The DC9025 grade is designed for steel and stainless steel applications under medium to rough turning conditions. The TNMG 45 geometry supports chip control and stable cutting in those materials.

“45” refers to the lead angle of the insert – a 45° approach angle which gives a good balance between strength and chip control in turning applications. Duracarb designates the TNMG 45 family as medium & roughing inserts

For this insert size (160412) the inscribed circle (IC) is 9.52 mm, thickness (S) is 4.76 mm and corner radius (RE) is 1.2 mm.

Duracarb’s upgrade of DC9025 features enhanced coating and substrate technology delivering ~20% higher feed capability and superior chipping resistance compared to older grades. This means better productivity and lower risk of tool failure under unstable conditions.

You can DM or WhatsApp us with your required quantity and job details, call our sales team for availability and bulk pricing, and we’ll confirm stock, shipping time and offer you the best rate. Send us a message today to get started.