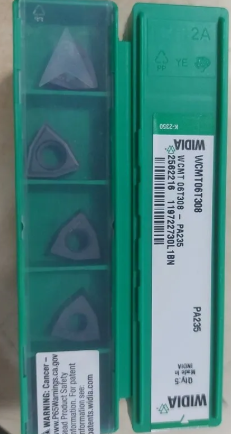

Widia SDMT 1204PDR PA120/WU20PM

The WIDIA SDMT 1204PDR PA120/WU20PM is a square-indexable milling/turning insert engineered for high productivity: PA120 grade with WU20PM PVD coating for superb wear resistance and surface finish across steel, stainless and alloys. Ideal for high-output shops seeking lower cost per part.

Looking to reduce tool change-downtime and lower cost per component? The WIDIA SDMT 1204PDR PA120/WU20PM is built to deliver. With a robust square-form SDMT geometry (IC 12.7 mm / ~0.5″, thickness ~4.8 mm) it gives four cutting edges per insert for milling and turning applications.

Key Features & Specifications:

-

Geometry: SDMT 1204 PDR (square indexable insert) — compact but rigid, ideal for both light and general machining.

-

Grade: PA120 (indicates the material/grade specification)

-

Coating / Insert Material: WU20PM PVD-coated microfine carbide — offers improved wear resistance and strength, working in steel, stainless steel & high temperature alloys.

-

Cutting Applications: Suitable for turning, milling (face, slot, shoulder) and drilling under certain setups. The square insert provides versatility across operations.

-

Performance: Built to handle demanding conditions — supports dry or wet machining. The robust grade and coating resist breakage and deliver longer tool life in general, stainless and high-temp alloy applications.

Why It’s a Best Seller:

Because in real-shop terms:

-

You spend far less time changing inserts — the PA120/WU20PM combo lasts significantly longer than standard grades under similar cutting conditions.

-

Surface finish improves thanks to the stable geometry and strong coating — giving better parts right off the machine.

-

Down-time is reduced: fewer insert changes, fewer interruptions.

-

Cost-per-part drops — higher productivity + less frequent tooling = better margins.

-

Trusted brand and variant — operators know WIDIA quality; procurement teams trust predictable inventory and performance.

Application Industries:

-

Automotive manufacturing — engine blocks, gear housings, transmission components

-

Aerospace & defence — structural aluminium alloys, stainless turned components

-

Die & mould industry — high-precision steel moulds, toolrooms needing long-life inserts

-

General engineering — job shops working steels, stainless, alloyed materials in high output.

Call-to-Action:

You May Also Like

Frequently Asked Questions

This insert (PA120/WU20PM grade) is optimized for steels, stainless steels and high temperature alloys — great for general and tougher machining.

While the SDMT square insert geometry is often used in milling, many setups use it for turning and even drilling operations when the toolholder allows it — versatility is one of its strengths.

For the SDMT 1204 family the thickness is ~4.8mm (0.189″) and the corner radius (Rε) is ~1.2 mm (0.047″) in some variants.

Because the PA120 base grade plus the WU20PM PVD coating deliver better wear resistance and durability. That means fewer tool changes, better productivity and lower cost per component — especially in high-volume production.

The SDMT 1204 PDR variant offers 4 cutting edges per insert thanks to its square geometry and indexable design. This enhances value and reduces tooling costs by spreading cost over multiple edges.