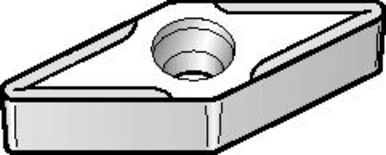

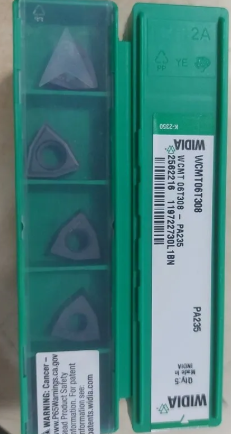

Widia DNMG11040426 TN2000

Elevate your CNC machining with the DNMG 110404 26 TN 2000 carbide insert. Designed for precision turning, it offers enhanced wear resistance and superior surface finish.

The DNMG 110404 26 TN 2000 carbide insert is engineered for high-performance turning applications. Its robust design ensures minimal downtime and consistent part quality, making it a preferred choice for professionals seeking reliability and efficiency.

Key Features & Specifications:

-

Geometry: Negative 55° rhombic insert for efficient chip control.

-

Grade: PC9030 – optimized for general machining of steel and stainless steel.

-

Coating: PVD coating for enhanced wear resistance and heat stability.

-

Cutting Applications: Ideal for turning operations requiring precision and durability.

Why It’s a Best Seller:

The DNMG 110404 26 TN 2000 insert is favored for its exceptional wear resistance and consistent performance, leading to reduced tool changes and improved surface finishes.

Application Industries:

-

Automotive: Precision machining of engine components.

-

Aerospace: Manufacturing of critical parts with stringent tolerances.

-

General Engineering: Versatile use in various machining applications.

CALL -TO-ACTION

You May Also Like

Frequently Asked Questions

This insert is suitable for machining steel and stainless steel materials.

The PVD coating enhances wear resistance and heat stability, extending tool life.

Recommended cutting speeds can vary; consult the manufacturer's guidelines for optimal performance.

Yes, the DNMG 110404 26 TN 2000 insert is versatile and can be used for both roughing and finishing operations.

The insert is designed to be compatible with most CNC machines; however, always verify compatibility with your specific machine model.