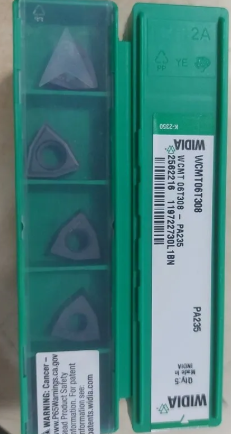

Widia 44315523 TN4000

WIDIA 44315523 TN4000 is a high-performance parting-off / grooving carbide insert with TiN-TiCN-Al₂O₃-TiN multilayer CVD coating. Designed for heavy cuts, interrupted cuts, and tough materials like steel & stainless steel. Delivers long wear life, excellent finish, reduced downtime.

The 44315523 TN4000 insert from WIDIA is crafted for demanding parting and grooving operations. Its TN4000 grade carbide substrate is enhanced with a multi-layer CVD coating (TiN-TiCN-Al₂O₃-TiN) to resist abrasion, thermal damage, and crater formation. It thrives under heavy depth-of-cut and interrupted cutting, keeping edges sharp for longer periods. Applicable for a broad range of materials—steel, stainless steel, cast iron. Whether for batch production or precision parts, it reduces the frequency of insert changes, improves surface finish, and lowers cost per component. CNC Tools Depot offers reliable supply, bulk pricing, and responsive customer support.

Key Features & Specifications:

-

Part Number / Geometry: 44315523, WIDIA TN4000 grade, parting‐off / grooving insert.

-

Grade: TN4000 – a premium CVD / multi-layer coated carbide grade emphasizing high wear resistance under heavy cuts.

-

Coating: TiN-TiCN-Al₂O₃-TiN (multi-layer CVD) – for abrasion resistance, heat stability, good crater resistance.

-

Applications: Excellent for parting off / grooving, heavy interrupted cuts; handles steel, stainless steel, cast iron etc.

Why It’s a Best Seller:

-

Less Downtime: The TN4000 grade holds up well under harsh conditions — heavy depth of cut, interrupted cuts — so you replace inserts less often.

-

Better Surface Finish: The multi-layer coating helps maintain sharp cutting edges longer, reducing edge build-up & chatter at cut-off / grooving → finer finish.

-

High Wear & Heat Resistance: The Al₂O₃ layer gives thermal protection; combined with TiCN etc, it resists abrasion & crater wear. Useful in moderate to high cutting speeds.

Industries & Use-Cases

-

Automotive components manufacturing (shafts, flanges, gears)

-

Aerospace (grooving / parting operations, stainless steel / alloy parts)

-

Die & Mold shops (where precision parting & groove edges matter)

-

General engineering & heavy fabrication (steel / cast iron work, batch & high volume)

You May Also Like

Frequently Asked Questions

It performs exceptionally on steel, stainless steel, and cast iron. The TN4000 grade handles tough, abrasive materials and interrupted cuts well

It uses a multi-layer CVD coating: TiN → TiCN → Al₂O₃ → TiN. The layers provide excellent wear resistance (abrasion), heat protection (thermal stability), and reduced crater wear.

Yes. While it excels in heavy cuts / interrupted cutting (roughing), its coating and design also support good edge stability for finishing in parting & grooving where precision matters. However, for ultra-fine finishing you might use inserts with very small radius or specialized coatings.

By lasting longer (fewer insert changes), maintaining sharp edges (less rework / scrapped workpieces), reducing tool-change downtime, and sustaining higher cutting speeds. All these contribute to lower operational cost per part.

For standard stock in India, we can supply quickly. For large / bulk volumes, we offer special pricing & can confirm current stock shortly. Send a WhatsApp / Call / DM to get today’s availability and best bulk rates.