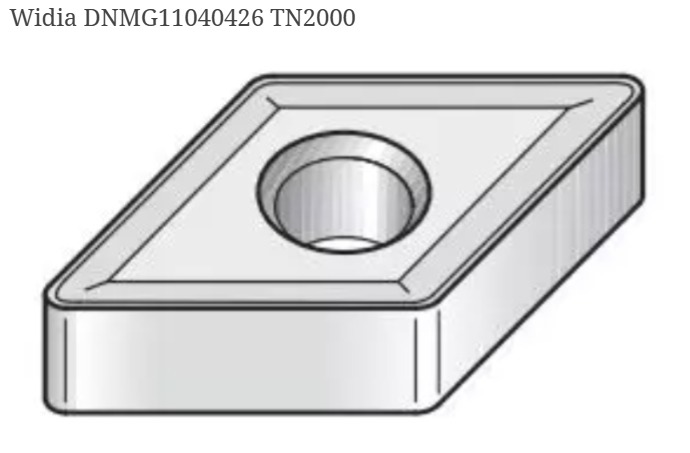

Widia SNUN190412 TTS

Achieve longer tool life, smoother finishes, and lower cost per part with the Widia SNUN190412 TTS carbide insert — a reliable, high-performance turning solution for steel and general engineering. DM/WhatsApp CNC Tools Depot to get the latest price and availability.

- Widia SNUN190412 TTS – High-Performance Carbide Insert for Precision Turning

When your goal is consistent accuracy, long tool life, and reduced machining costs, the Widia SNUN190412 TTS delivers exactly that.

Built with Widia’s trusted carbide technology, this square-shaped negative insert ensures stable performance in medium to finishing operations on steel and general engineering materials.

Hook / Attention Line

“Cut more parts between insert changes — reduce your downtime, increase throughput.”

Introducing the Widia SNUN190412 TTS — a high-performance carbide insert engineered to deliver longer tool life, consistent cutting performance, and lower cost per component in turning operations.

Key Features & Specs:

-

Geometry / Insert Type: SNUN — square (S-style) negative insert, 90° corner, neutral (T) corner style, 4 cutting edges

-

Size / Nominal Dimensions: 19 × 04 × 12 (i.e. 19 mm inscribed circle, 4 mm depth, 12 mm width)

-

Grade / Material: TTS (uncoated, universal grade for steel) — good balance of hardness and toughness

-

Recommended Application: primarily for steel / carbon steels (ISO P class) in general turning work

Cutting Conditions & Use: suitable for straight or lightly interrupted cuts, medium feed & depth, stable setups -

Edge / Chip Control: well-balanced chip control in regular turning — designed for stable, repeatable performance

Why It’s a Best Seller

-

Less downtime, more uptime — the TTS grade offers predictable wear and avoids surprise failures

-

Better surface finish — stable geometry and chip control lead to fewer micro-scratches and rework

-

High wear resistance + toughness balance — handles typical steel turning conditions without chipping

-

Cost-effective choice — since it's uncoated, you avoid over-spending on coated inserts where not needed

-

Multiple edges per insert — the SNUN design gives you 4 workable edges, maximizing value

🏭 Application Industries

This insert is a strong choice across industries such as:

-

Automotive (shafts, axles, housings)

-

General engineering & fabrication

-

Heavy machinery components

-

Agricultural equipment

-

Industrial pumps, valves, etc.

📞 Call-to-Action

You May Also Like

Frequently Asked Questions

It is optimized for steel / carbon steels (ISO P class) in general turning operations. Because it’s uncoated, it handles typical steel conditions well without the risk of coating flaking.

The SNUN design offers 4 usable cutting edges (one per side) due to its square negative geometry.

It works best in continuous or lightly interrupted cuts. Heavy interruptions or roughing may demand a tougher or coated grade.

For stable setups, moderate feed and depth (based on your machine & steel grade) — consult your internal Widia or tooling catalog for the exact range matching SNUN & TTS. Use the insert until flank wear begins to affect surface finish.

-

For many standard steel turning tasks, an uncoated insert reduces cost while delivering reliable performance. Coated inserts excel in high-speed or harder materials. TTS is a balanced, economic choice where coating benefits are not essential.