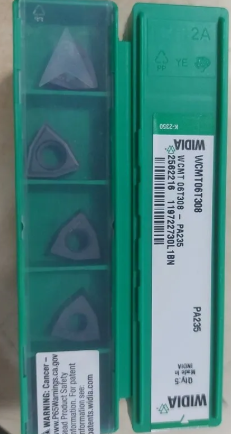

Widia WCMT050308 PA235

Discover the WIDIA WCMT050308 PA235 carbide insert – engineered for high performance in steel and cast-iron turning operations. With a positive geometry trigon shape (80°), PA235 grade carbide substrate and premium coating, it delivers longer tool life, reliable chip control and superior finish. Perfect for automotive, aerospace, die & mold and general engineering applications. Contact CNC Tools Depot now for bulk pricing and availability.

Cut Smarter. Last Longer. Machine Better.

Get unbeatable tool life and consistency with the WIDIA WCMT050308 PA235 — the insert trusted by machinists worldwide for precision turning and U-drilling in steel and cast iron. Designed using WIDIA’s advanced carbide technology, this insert ensures maximum productivity, fewer tool changes, and superior surface finish, even under demanding conditions.

Hook / Attention Line

Cut faster, stay running longer: the WIDIA WCMT050308 PA235 = fewer tool changes, lower cost per part.

Key Features & Specs

-

Geometry: WCMT 050308 (80° trigon insert) – robust shape offering multiple edges

-

Grade: PA235 – a high-performance carbide grade designed for steel and cast-iron machining.

-

Coating: Premium coating on carbide — while specific coating data for this exact insert isn’t fully detailed in our source, WIDIA’s tool catalog emphasises multilayer coated carbide for long tool life and high speed.

-

Insert material: Cemented carbide substrate – ensuring wear resistance and edge stability.

-

Typical dimensions: For the WCMT050308 variant: inscribed circle (IC) ≈ 7.94 mm, thickness ~3.18 mm, corner radius (Re) ~0.8 mm.

-

Cutting applications: Optimised for turning operations (especially steel/CI). Some listings also suggest use in drilling or U-drill adaptors

Why It’s a Best Seller

-

Longer tool life: The PA235 grade is built with a wear-resistant substrate and premium coating, resulting in extended edge life even on tough steels and cast irons.

-

Reduced downtime: With more edges per insert and a stable geometry, you spend less time swapping inserts and more time cutting.

-

Superior surface finish: The stable cutting edge and chip control minimise edge wear and vibration, yielding smoother finishes – crucial in automotive, aerospace and die & mold components.

-

High reliability: Backed by a global brand (WIDIA) and trusted in high-throughput machining environments – you’re buying confidence as much as insert.

🏭 Application Industries

-

Automotive – turning engine blocks, gear components, chassis parts in steel or cast iron.

-

Aerospace – machining structural steel or cast components where long tool life and finish are essential.

-

Die & mould – precision steel tooling, cast iron fixtures where surface quality and repeatability matter.

-

General engineering & job shops – for diverse steel/CI turning jobs demanding high productivity and low cost per piece.

You May Also Like

Frequently Asked Questions

The PA235 grade is optimised for steel and cast iron workpieces. Some sources list steel and cast iron as targeted materials for this insert.

This is an 80° trigon standard insert (WCMT), inscribed circle around 7.94 mm, thickness about 3.18 mm and a corner radius ~0.8 mm in typical listings.

Primarily it is used for turning (as per WIDIA’s turning insert catalog). Some distributors list it also for U-drill adaptors or drilling insert applications – but best tucked into a turning setup for optimal performance.

With higher wear-resistance, more stable edge, improved chip control and fewer insert changes, you can expect longer uninterrupted runs, fewer stoppages, better surface finishes and lower cost per component.

-

Yes – CNC Tools Depot, India’s largest marketplace for carbide inserts, stocks this product and can handle bulk orders. Contact them via DM, WhatsApp or call to check current stock, pricing and delivery lead-time.