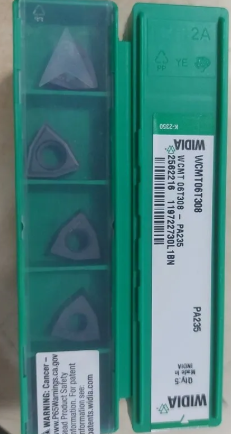

Widia SDMT 1204 PDRMH-PA120

Widia SDMT 1204 PDRMH-PA120 is a square (SDMT) carbide milling insert with PVD coating (TiAlN class), offering a universal grade for light to general machining of steels, stainless, and high-temperature alloys — ideal for high productivity and lower cost per part.

The Widia SDMT 1204 PDRMH-PA120 is a premium square milling insert engineered for productivity, reliability, and versatility in modern CNC machining. Designed with a double-sided SDMT geometry and PDRMH chipbreaker, this insert provides excellent chip evacuation and cutting stability — ensuring smooth machining and consistent surface finish.

Built on PA120 grade with advanced PVD TiAlN coating, it delivers superior wear resistance, thermal stability, and longer tool life across a wide range of materials. Whether you’re cutting steels, stainless steels, or high-temperature alloys, this insert maintains high performance under both wet and dry conditions.

Hook / Attention Line

“Cut more parts, change less inserts” — that’s the real benefit of the Widia SDMT 1204 PDRMH-PA120. Boost throughput, slash downtime, and lower your cost per component.

Key Features & Specs

-

Geometry & style: SDMT 1204 (square, double-ended) format, PDRMH chipbreaker style

-

Grade & coating: PA120 class (microfine carbide + PVD TiAlN or equivalent universal coating)

-

Cutting edges per insert: 4 usable edges

-

Insert size: IC = 12.7 mm (approx)

-

Corner radius / facet: typically ~1.2 mm corner radius (or in that ballpark)

-

Applications / recommended use: suited for medium to light milling in steels, stainless steels, and high temperature alloys (P, M, S class)

-

Versatility: can be used under wet or dry machining conditions (depending on setup

Why It’s a Best Seller:

-

Less downtime: Four edges per insert means you get more life before index or replacement.

-

High wear resistance: The PA120 / TiAlN PVD coating improves resistance to flank wear and crater wear, giving you stable performance across batch runs.

-

Better surface finish: The chipbreaker geometry ensures consistent chip control and smooth cutting, reducing chances of chatter.

-

Lower cost per part: Because you extract more life and maintain cutting stability, your effective cost per component goes down.

-

Reliability under variation: Works well across a range of materials — less need to swap brands/grades when material mix changes.

🏭 Application Industries

Automotive parts (engine components, transmission parts), Aerospace (light alloys, high-temp alloys), Die & Mold (steel, stainless mold steels), General Engineering and Job Shops working with steels, cast steels, stainless, superalloys.

📞 Call-to-Action

You May Also Like

Frequently Asked Questions

It excels in steels, stainless steels, and high-temperature alloys (P / M / S classes). The universal nature of the PA120 grade gives you flexibility when material mixes vary.

While coolant often helps in heavy cuts, the PVD TiAlN coating and robust substrate of this insert allow usage in dry or minimum quantity lubrication (MQL) setups, depending on your machine and rigidity.

The PDRMH chipbreaker is designed for good chip control, stable cutting, and consistent performance across varying radial depth—helpful for maintaining surface finish and reducing recutting or chip clogging.

This insert offers 4 usable cutting edges (two faces × two directions) before needing replacement or re-indexing.

Because it comes from Widia — a trusted name in cutting tools — ensuring better consistency, materials, coatings, and global support. Combined with the performance advantages above, it often gives lower total cost of ownership compared to unbranded inserts.