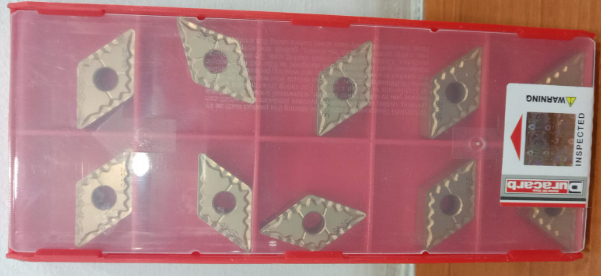

Korloy VNMG160404-HA H01

“Boost your turning performance: Korloy VNMG160404-HA H01 delivers superior surface finish, long edge life, and stable chip control — ideal for finishing and light semi-finishing in steel, cast iron & nonferrous metals. DM or WhatsApp us for price & stock today!”

Korloy VNMG160404-HA H01 – Precision Turning Insert for Superior Finish & Tool Life

The Korloy VNMG160404-HA H01 is a high-performance carbide insert engineered for finishing and semi-finishing turning operations. With its 35° rhombic (diamond) negative geometry and HA chipbreaker, this insert delivers stable chip control, lower cutting forces, and outstanding surface finishes in steels, cast iron, and non-ferrous materials.

Hook / Attention Line

“Upgrade your productivity: one insert that fights edge wear, boosts tool life, and slashes cost per part.”

Key Features & Specs

-

Geometry & Type: VNMG (35° diamond / rhombic) negative-type indexable insert.

-

Dimensions / Key geometry:

- Cutting edge length (B1): ~ 16.6 mm

- Inscribed circle diameter (IC): 9.525 mm (equivalent to 3/8″)

- Thickness: 4.76 mm

- Corner radius (rε): 0.4 mm -

Chipbreaker / Face style: HA chipbreaker (dual-face chipbreaker) for medium and finishing operations.

-

Grade / Substrate / Coating: Grade H01 (Korloy’s uncoated / polished ultra-fine carbide substrate) — often used for cast iron, nonferrous, and certain steels.

-

Relief / Clearance Angle: It is a 0° major clearance (zero-relief) style for its negative insert type.

-

Mounting / Hole: Bore with 3.81 mm fixing hole.

-

Hand / Orientation: Neutral / standard orientation (not left/right).

Why It’s a Best Seller

-

Longer Tool Life & Reduced Downtime — The ultra-fine substrate of the H01 grade resists edge degradation under finishing cuts, giving more parts per edge.

-

Stable Chip Behavior & Surface Finish — The HA chipbreaker ensures predictable chip control and low cutting force, reducing chatter and enhancing surface quality.

-

Lower Cost per Component — You replace inserts less frequently, reducing tool change interruptions and scrap.

-

High Wear & Chipping Resistance — In finishing or semi finishes, the insert resists flank wear and edge chipping better than generic grades.

-

Versatility in Machining — Because of neutral orientation and balanced geometry, it fits many standard turning holders and can serve across multiple part types.

These practical gains are why this model is widely stocked and requested by turning shops — it gives a dependable finishing insert with solid lifecycle characteristics.

Industries uses

-

Automotive — precision shafting, housings, small engine components

-

Aerospace / Defense — finishing of nonferrous or cast structural parts

-

Die & Mold / Tooling — final passes on mold inserts, cores, cavities

-

General Engineering & Fabrication — small to medium runs on steel, castings, nonferrous parts

-

Pump / Valve / Hydraulic Components — where tight tolerances and good surface finish are needed

Cutting Applications & Material Suitability

-

Designed for turning / external turning applications (negative insert geometry).

-

Suitable for finishing or light to medium semi-finishing passes (thanks to HA chipbreaker).

-

Works well on cast iron, nonferrous materials, and certain steels (as per Korloy reference for H01 grade)

-

Because H01 is uncoated / polished, it is less ideal for highly abrasive or heavy interrupted steels — but in stable finishing cuts it offers low friction and consistent edge performance.

Call-To-Action

Related Products

You May Also Like

Frequently Asked Questions

It’s ideal for finishing or light semi finishing in turning on cast iron, steels, and nonferrous metals where a good surface finish and low cutting force are priorities.

HA is Korloy’s chipbreaker style optimized for medium / finishing operations — it promotes controlled chip flow, low cutting forces, and consistent edge behavior.

It is essentially an uncoated / polished ultra-fine carbide substrate grade. This gives it lower friction and good performance in stable finishing cuts without abrasive loading.

The insert is 4.76 mm thick, inscribed circle 9.525 mm, with a 0.4 mm corner radius, and cutting edge length ~16.6 mm. It’s a negative insert with HA chipbreaker on both sides.

You can DM us, WhatsApp, or call CNC Tools Depot. We maintain bulk stock of Korloy inserts and can provide immediate quotations, lead times, and discount tiers for bulk orders.