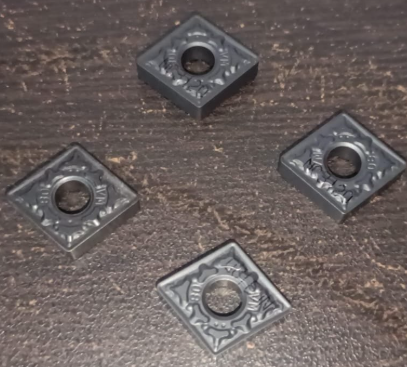

Korloy WNMG080408-VP3 PC5300

Upgrade your turning performance. The KORLOY WNMG 080408 VP3 with grade PC5300: universal PVD-coated carbide insert delivering high wear & chipping resistance across steel, stainless steel and cast iron. Ideal for demanding production. Available now at CNC Tools Depot.

Boost Your Machining Performance with KORLOY WNMG 080408 VP3 PC5300 – The Universal Solution for Precision Turning

When productivity, surface finish, and cost per component matter — the KORLOY WNMG 080408 VP3 PC5300 delivers. Engineered with KORLOY’s advanced PC5300 grade and optimized VP3 chip breaker geometry, this insert is designed to handle a wide range of materials — from steel and stainless steel to cast iron and heat-resistant alloys — with outstanding wear resistance and edge strength.

Hook / Attention Line

Slash your cost per component — run longer, cut faster, and change less often. The KORLOY WNMG 080408 VP3 PC5300 insert is built for productivity.

Key Features & Specs

-

Geometry: WNMG 080408 (80° rhombic negative insert, designation “0804” size) with chip breaker VP3. According to KORLOY data the VP3 chip-breaker is optimised for medium cutting, strong chip control at higher depths of cut, and reduced cutting loads.

-

Grade & Coating: Grade PC5300, PVD coated with superb high-temperature hardness and oxidation-resistance. Described as a “Universal grade for stainless, HRSA, steel and interrupted cast iron machining – high chipping and welding resistance for longer tool life”.

Application Types: Designed for turning (negative insert), and as part of the PC5300 series, also applicable for milling and drilling applications of steel, stainless steel, cast iron, heat-resistant alloys.

Typical size reference: For WNMG 080408, IC ≈ 12.7 mm, thickness 4.76 mm, inscribed circle size “08” series. (According to KORLOY catalogue typical “08” size d = 12.7 mm). -

Cutting Conditions & Materials: With the VP3 chip breaker, for example WNMG 080404-VP3 is listed for fn (feed) ~0.10-0.45 mm/rev and ap (depth) ~0.50-5.00 mm (medium to finishing turning) in various materials.

Why It’s a Best Seller:

-

Minimise downtime: With the universal PC5300 grade you don’t need to stock a multitude of grades for different materials — one grade covers steel, stainless steel, cast iron, HRSA. That simplifies your insert inventory.

-

Longer tool life & fewer changes: The PVD coating and ultra-fine grain substrate design offer high wear resistance and strong edge strength, resisting chipping and welding-on work-piece material.

-

Superior chip control & surface finish: The VP3 chip breaker gives stable chip evacuation even at deeper cut depths, fewer built-up edge issues, leading to better surface finishes and consistent part quality.

-

Cost-effective: By cutting faster, running longer, and reducing tool changes, you cut your cost per component — more parts between indexings, less idle time, fewer scrap parts.

🏭 Application Industries

-

Automotive & auto-components (shafts, housings, high volumes)

-

Aerospace (machining stainless, HRSA components)

-

Die & mould manufacturing (turning of steels, stainless steels)

-

General engineering (mixed materials production, making life easier with one universal insert grade)

📞 Call-to-Action

Related Products

You May Also Like

Frequently Asked Questions

This insert is built using grade PC5300, a universal PVD coated grade suitable for steel, stainless steel, cast iron, and heat-resistant alloys (HRSA).

The VP3 chip breaker is optimised for medium cutting operations. It provides stable chip control and reduced cutting loads even at deeper depths of cut, making it suitable for higher productivity operations.

Yes — while the specific designation WNMG 080408 is a turning insert (negative style, 80° rhombic), the PC5300 grade itself is described as applicable to turning, milling and drilling for a wide range of materials.

Thanks to its longer tool life (due to wear & chipping resistance), fewer indexings, fewer tool changes, and the ability to standardise on one grade across multiple materials, you save on tool inventory, reduce downtime and increase parts-per-insert — resulting in lower cost per component.

It’s ideal for high-volume turning in automotive, general engineering, aerospace, die & mould. Where you require consistent surface finish, minimal tool change time and machining a variety of materials (steel, stainless, HRSA) — this insert delivers.