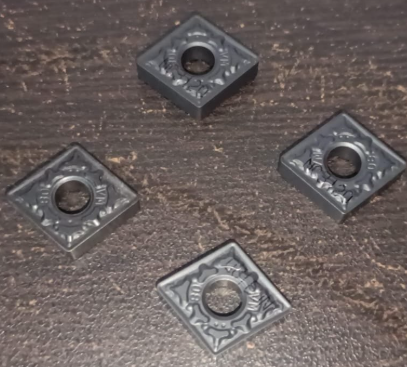

Korloy TNMG 160408 MM NC9115

The Korloy TNMG 160408 MM NC9115 is a high-performance turning insert designed for precision machining of steel and alloy steel. Featuring a triangular, negative-type geometry (TNMG) with a double-sided cutting edge, this insert ensures superior cost-efficiency and durability.

The MM chipbreaker provides stable chip control and excellent surface finish in medium machining conditions, while the NC9115 grade is engineered with advanced CVD coating technology, offering outstanding wear resistance, toughness, and extended tool life - even at higher cutting speeds.

Features

-

Insert Type: TNMG 160408 (Triangular, Negative, Double-Sided)

-

Grade: NC9115 (CVD-coated carbide for steel turning)

-

Chipbreaker: MM (optimized for medium cutting, stable chip evacuation)

-

Cutting Application: Medium machining of steel and alloy steel

-

Geometry: High edge strength, designed for balanced wear resistance and toughness

-

Performance: Excellent surface finish, reduced cutting forces, extended tool life

Applications

-

General steel turning (medium cutting)

-

Suitable for automotive, heavy machinery, and general engineering industries

-

Optimized for CNC lathes and automated machining centers

Advantages

-

Long tool life due to NC9115 grade with superior wear resistance

-

Stable cutting in medium machining with MM chipbreaker

-

Reduced downtime with reliable performance across varied cutting conditions

-

Cost-effective double-sided insert with multiple cutting edges

You May Also Like

Frequently Asked Questions

This insert is mainly used for medium turning of steel and alloy steel. Its MM chipbreaker ensures stable chip control and smooth machining, while the NC9115 grade provides excellent wear resistance and long tool life.

-

T = Triangle shape

-

N = 0° relief angle (negative type insert)

-

M = Tolerance class (medium)

-

G = Hole with chipbreaker

-

160408 = Size code (16 mm inscribed circle, 4.76 mm thickness, 0.8 mm nose radius)

NC9115 is a CVD-coated carbide grade from Korloy, specially designed for turning steel at medium speeds. It offers high wear resistance, toughness, and extended tool life, making it reliable for CNC machining.

Yes. Being a TNMG insert (negative geometry), it has 6 cutting edges (3 per side), providing a cost-effective solution.

It is compatible with CNC lathes, turning centers, and conventional machines that accept TNMG-type tool holders.

This grade is primarily optimized for steel and alloy steel. For stainless steel (ISO M) or cast iron (ISO K), Korloy offers other grades better suited to those materials.

You can buy authentic Korloy TNMG 160408 MM NC9115 inserts online at CNC Tools Depot – the world’s largest carbide inserts marketplace.