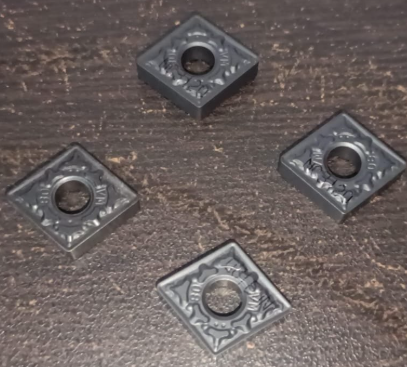

Korloy TNMA160408 NC6310

Boost productivity with the Korloy TNMA160408 NC6310 carbide insert. Designed for high-speed, continuous or light interrupted turning of cast iron, offering superior wear and chipping resistance.

The Korloy TNMA160408 NC6310 carbide insert is engineered for high-speed, continuous or light interrupted turning of cast iron. Featuring a CVD coating with improved wear and chipping resistance, it ensures stable tool life and enhanced surface finish.

Key Features & Specifications:

-

Grade: NC6310 – High-speed turning for cast iron

-

Coating: CVD with enhanced wear & chipping resistance

-

Geometry: TNMA160408 – Negative triangular insert

-

Chip Breaker Options: MK (Medium) & RK (Rough)

-

Applications: Ideal for gray & ductile cast iron

Why It’s a Best Seller:

Designed for high-speed, continuous or light interrupted turning, the NC6310 offers superior wear resistance and stable tool life, reducing downtime and improving surface finish.

Industries Served:

Automotive, Aerospace, Die & Mold, General Engineering

Call-to-Action:

Related Products

You May Also Like

Frequently Asked Questions

This insert is ideal for turning gray and ductile cast iron, particularly in high-speed, continuous or light interrupted conditions.

The NC6310 grade offers enhanced wear resistance, chipping resistance, and stable tool life, making it suitable for demanding machining tasks.

Yes, the NC6310 grade performs well in both dry and wet machining conditions, providing flexibility in various setups.

The TNMA160408 NC6310 insert is compatible with MK (Medium) and RK (Rough) chip breakers, allowing customization based on specific machining needs.

You can contact CNC Tools Depot for pricing, availability, and bulk orders of the Korloy TNMA160408 NC6310 carbide insert.