Korloy MGMN300-M NC6315

Introducing the MGMN 300 M NC6315 carbide insert – engineered for long tool life, superior surface finish and cost-per-component savings. Ideal for turning, milling and drilling cast iron in automotive, aerospace, die & mould and general engineering. Ask CNC Tools Depot now for price and bulk availability.

- Power Through Cast Iron Machining with Confidence

Experience longer tool life, superior wear resistance, and consistent performance with the Korloy MGMN 300 M NC6315 carbide insert – now available at CNC Tools Depot, India’s largest marketplace for carbide inserts. Engineered using Korloy’s advanced NC6315 grade technology, this insert is designed to deliver exceptional stability and reliability in the most demanding grooving and parting operations on cast iron materials.

Hook / Attention Line

Want longer tool life, faster cutting and reduced cost per component? Meet the MGMN 300 M NC6315 – your game-changer for high-productivity machining.

Key Features & Specs

-

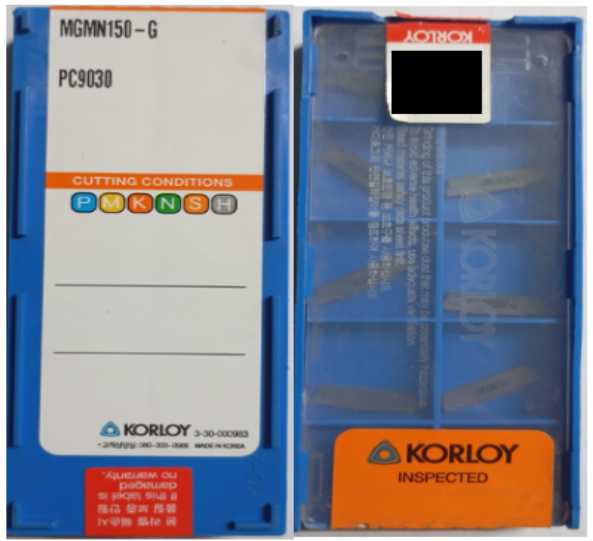

Insert designation: MGMN 300 M (grooving/turning form) with grade NC6315 from KORLOY.

-

Grade: NC6315 (ISO K15) – a CVD‐coated grade developed for general and high-feed, highly interrupted machining of grey cast iron and ductile cast iron.

-

Coating / substrate: Improved alumina coating layer (greater wear and welding resistance) + titanium layer for improved fracture resistance + functional substrate optimized for high-feed heavy-interrupted cutting.

-

Geometry / chip-breaker: Designed with strong flat lands and wide support area to resist chipping under vibration, and chip breakers MK (for medium cutting) and RK (for roughing, heavy interruption) specially developed for this grade.

-

Application scope: While NC6315 is particularly described for cast iron turning– it can be translated to grooving/turning applications requiring high stability under heavy load and interruption. Example application range: Depth of cut, feed values under heavy interruption.

-

Benefits: Stable tool life (less variation), improved surface finish (optimized cutting edge), excellent wear and chipping resistance in tough materials.

Why It’s a Best Seller

-

Less downtime: With superior wear and chipping resistance, you spend less time changing inserts and more time cutting.

-

Better surface finish: Optimised edge geometry and coatings reduce built-up edge and flank wear, so your parts come out cleaner.

-

High wear resistance = lower cost per component: Longer insert life means fewer inserts per job, reducing tooling cost and making your process leaner.

-

Trusted grade: The NC6315 grade is established for demanding cast-iron applications under high feed / high interruption—so if you switch to it you’re using a proven performer.

🏭 Application Industries

-

Automotive (e.g., cast-iron engine blocks, brake drums, transmission housings)

-

Aerospace (where cast iron or heavy interrupted turning may apply)

-

Die & Mould (large cast-iron bases, heavy turning)

-

General Engineering / Heavy Machinery (components made of grey or ductile cast iron, where high feed or interrupted cuts are common)

Related Products

You May Also Like

Frequently Asked Questions

The NC6315 grade is specifically developed for grey cast iron and ductile cast iron, especially under high feed and highly interrupted cutting conditions.

While the published data from the manufacturer emphasises turning of cast iron with heavy interruption, the MGMN 300 M geometry (grooving/turning type) may be applicable for certain milling/grooving operations where the holder supports it. We recommend confirming holder compatibility for your machine application.

NC6315 (K15) offers higher resistance to wear, chipping and fracture in high-feed / heavy-interruption cutting versus NC6310 (K10) which is optimised for high speed with light interruption.

For NC6315 the MK chip breaker is recommended for medium cutting / continuous cutting conditions, offering improved surface finish. The RK chip breaker is your choice for roughing, heavy interruption, high depth of cut applications.

-

You can DM, WhatsApp or call us at CNC Tools Depot with your required quantity, holder type and insert code (MGMN 300 M NC6315). We’ll check stock, supply lead-time and provide best bulk pricing. Stock is dispatched promptly from our Faridabad facility with pan-India delivery.