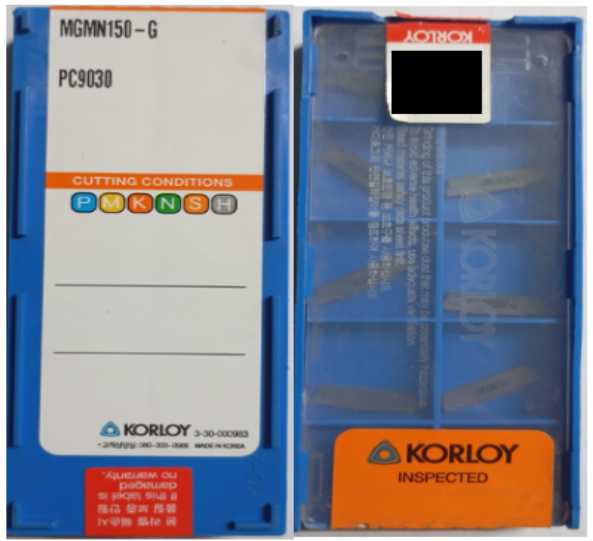

Korloy MGMN300-G PC5300

Maximise productivity with the Korloy MGMN300‑G PC5300 carbide insert — a high-performance grooving / turning insert with PC5300 grade for steel, stainless & cast iron. Ideal for CNC machining in automotive, aerospace, die & mould and general engineering.

Cut Faster. Last Longer. Save More.

The Korloy MGMN300-G PC5300 is a high-performance carbide grooving insert from Korloy’s trusted MGT (Multi Grooving Tools) series, engineered for exceptional tool life, reliable chip control, and reduced machining cost per component.

This insert combines Korloy’s advanced PC5300 PVD coating technology with a tough fine-grain substrate, ensuring stable performance across steel, stainless steel, and cast iron applications. Whether you’re roughing, finishing, or performing multi-groove turning operations, the MGMN300-G PC5300 delivers unmatched cutting stability and productivity.

Hook / Attention Line

Cut faster, tool less often — reduce cost per part! With the Korloy MGMN300-G PC5300 insert you get longer tool life, higher cutting speeds, and reduced downtime — all critical for high-volume CNC operations.

Key Features & Specs

-

Geometry: MGMN300-G series (width of cutting edge approx 3.0 mm for the 300 designation) as part of the MGT (Multi Grooving Tools) insert family from Korloy.

-

Grade/Coating: PC5300 — PVD-coated, designed for “high speed machinability / stable machinability / interrupted machinability” across steel (P, M), cast iron (K) and non-ferrous (N) applications.

-

Substrate: Toughened substrate with fine grain structure and anti-oxidation coating for versatile performance (steel, stainless, cast iron, heat-resistant super alloys) per Korloy’s catalogue.

-

Applications: Suitable for grooving / parting-off / turning operations (as part of the MGT range) — especially where strong chip control and surface finish matter.

-

Typical machining outline: In the MGT Plus series, Korloy references PC5300 as a universal PVD grade for general-purpose, roughing and interrupted cuts.

Why It’s a Best Seller

-

Less downtime & fewer insert changes: The PC5300 grade offers high speed and stability — meaning you can run longer between changes and get consistent performance across job batches.

-

Better surface finish: Thanks to the MGT geometry and optimized chip breaker design, you’ll get improved surface roughness and chip flow, particularly in turning/grooving operations.

-

High wear- and chipping-resistance: The tough substrate plus effective PVD coating means the insert can handle interrupted cuts, harder materials and higher feed rates — reducing tooling cost per component.

-

Versatility: One insert for multiple operations (grooving + turning) reduces tooling inventory and simplifies workflow — a practical benefit for production shops.

🏭 Application Industries

-

Automotive: For high volume engine / transmission parts machining (materials: steel, cast iron)

-

Aerospace: When machining high strength alloys or stainless components where surface finish and reliability matter

-

Die & Mould: Precision grooving and turning of mould steels

-

General Engineering: Workshops servicing varied materials and needing one-tool solutions for grooving/turning

📞 Call-to-Action

Related Products

You May Also Like

Frequently Asked Questions

The PC5300 grade is a PVD-coated, high-speed versatile grade from Korloy designed for stable machining across steel, stainless and cast iron — offering improved wear resistance, chipping resistance and reliable performance in interrupted cuts.

Yes — the MGMN300-G geometry belongs to Korloy’s MGT family, which is developed for multi-grooving, parting-off and turning. That means you can use it in grooving/parting as well as external turning operations, offering flexibility.

According to Korloy’s catalogue, the PC5300 grade is suitable for P-class (carbon/low alloy steels), M‐class (alloy steels), K-class (cast irons) and N-class (non-ferrous) materials — making it a good general use choice

Because of its higher tool life (fewer indexings/changes), stable cutting at higher speeds/feeds, and the ability to handle varied operations (grooving + turning), you reduce downtime, tooling inventory and improve machine utilisation — all contributing to lower cost per part.

Ensure you select the correct width (300 denotes approx. 3.0 mm cutting edge for the MGMN series), correct hand (G denotes specific hand / geometry), correct grade (PC5300), and compatibility with your holder. Also check stock availability and pricing at CNC Tools Depot for bulk orders.