Korloy MGMN300-02-M NC3120

Korloy MGMN300-02-M NC3120 is a high-performance grooving insert optimized for steel machining. The NC3120 CVD-coated grade delivers superior wear and heat resistance, while the M-type chipbreaker ensures stable chip control and smooth cutting — ideal for productivity and consistent quality in CNC operations.

- Korloy MGMN300-02-M NC3120 – Engineered for Precision Grooving in Steel Machining

When performance, reliability, and surface finish matter most — the Korloy MGMN300-02-M NC3120 delivers. Designed for high-precision grooving and parting applications, this insert combines Korloy’s latest CVD coating technology with advanced chipbreaker geometry to achieve superior productivity in steel machining.

Hook / Attention Line

Maximize Your Groove — Longer Tool Life, Higher Stability, Cleaner Finishes!

Key Features & Specs

The Korloy MGMN300-02-M NC3120 is a CVD-coated carbide grooving insert designed for precision external and internal grooving of steels under both continuous and interrupted cutting conditions. Its M-geometry chipbreaker delivers excellent chip evacuation and smooth cutting even in medium feed rates, helping machinists achieve consistent surface quality with minimal vibration.

-

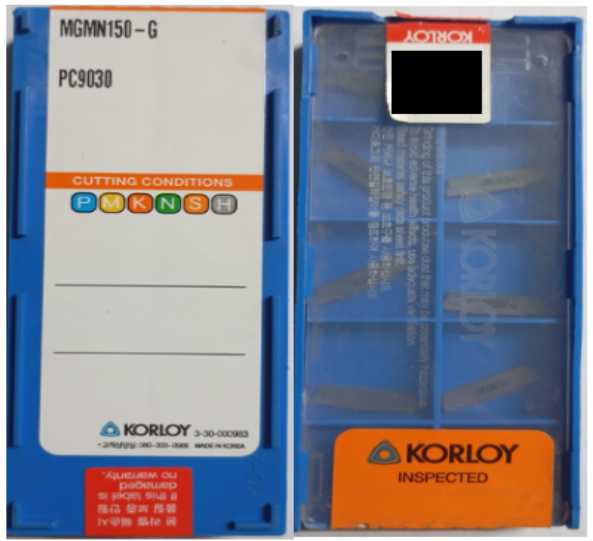

Insert Type: MGMN300-02-M

-

Grade: NC3120 (Korloy proprietary CVD-coated carbide)

-

Geometry: M-type chipbreaker for stable cutting in steel grooving

-

Coating: TiCN + Al₂O₃ + TiN CVD multilayer coating

-

Application: Ideal for external & internal grooving of carbon steel and alloy steel

-

Machining Range: Stable in medium to high-speed conditions

Why It’s a Best Seller

-

🧱 Exceptional Wear Resistance: NC3120’s thick Al₂O₃ layer extends tool life in long production runs.

-

⚙️ Reliable Chip Control: M-type breaker design ensures consistent chip flow, preventing built-up edge and tool damage.

-

💨 Higher Cutting Efficiency: Delivers faster cutting speeds with stable performance — reducing downtime.

-

💎 Superior Surface Finish: Produces clean, precise grooves for parts requiring tight dimensional accuracy.

🏭 Application Industries

Perfect for machining in:

-

Automotive Components (shafts, housings, fittings)

-

General Engineering (tool holders, mechanical parts)

-

Hydraulic & Pneumatic Parts

-

Aerospace Fasteners

Related Products

You May Also Like

Frequently Asked Questions

It is optimized for steel machining (P group), including both carbon and alloy steels, under stable or slightly interrupted cutting conditions.

NC3120 features a CVD multilayer coating (TiCN + Al₂O₃ + TiN) that offers excellent heat and wear resistance, making it suitable for high-speed operations.

It’s primarily a grooving insert, but depending on toolholder compatibility, it can handle light parting operations with controlled depth.

NC3120 provides a balance between toughness and wear resistance — ideal for medium cutting conditions, whereas NC3030 is more wear-resistant for stable cuts and NC3125 is tougher for interrupted cuts.

You can purchase 100% genuine Korloy inserts exclusively from CNC Tools Depot – India’s Largest Marketplace for Carbide Inserts. Contact us directly on WhatsApp or Call for stock and price updates.