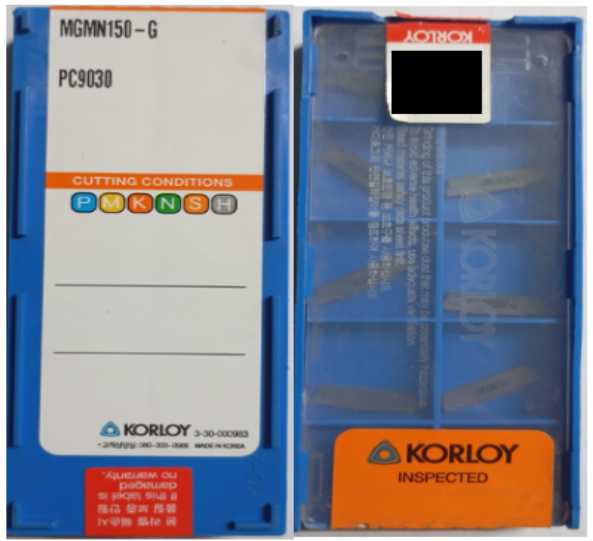

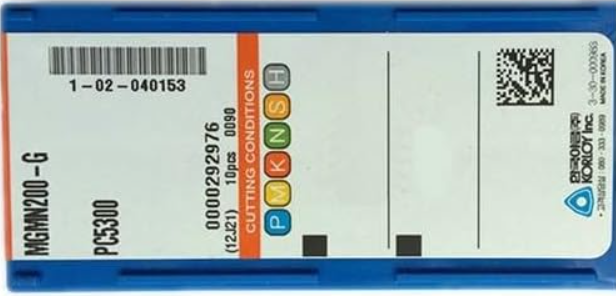

Korloy MGMN150-G PC9030

Korloy MGMN150-G PC9030: 1.5 mm grooving insert with PC9030 CVD coating, engineered for stainless steel. Ideal for precise slotting, parting off, and multi-operation MGT setup.

"Maximise productivity with the Korloy MGMN150-G PC9030—groove smoother, last longer, and slash cost per part!"

The Korloy MGMN150-G PC9030 is a premium grooving insert featuring a 1.5 mm cutting width and a 0.15 mm corner radius, with a robust PC9030 CVD coating designed for machining stainless steel. Its chip breaker ensures efficient, narrow chip formation, improving chip flow and reducing downtime. Compatible with the versatile MGT system, it enables grooving, turning, facing, and copying using a single holder—enhancing productivity, stability, and tool life. Perfect for the automotive, aerospace, die & mold, and general engineering sectors, this insert is a high-performance, multi-functional staple in any CNC setup.

Key Features

-

Geometry: MGMN series, square grooving insert with a 1.5 mm cutting width and 0.15 mm corner radius (R).

-

Grade & Coating: PC9030 grade—CVD-coated specially for tough materials like stainless steel, offering robust wear and chipping resistance.

-

Dimensions: d = 1.2 mm (width of groove), t = 3.5 mm (thickness), insert length approximately 16 mm.

-

Cutting Application: Optimised for grooving (slotting, parting off) — part of Korloy's versatile MGT system, compatible with multiple operations such as turning, facing, and copying using the same holder.

Why It's a Best Seller

-

Longer tool life & reduced downtime: The PC9030 grade’s high toughness substrate and CVD coating significantly improve wear and chipping resistance, cutting replacement frequency.

-

Superior chip control: The specifically designed chip breaker produces narrower chips, enhancing chip flow and reducing clogging—saving spindles from breakdowns.

-

Versatility = fewer holders: Kept in as part of the MGT series, it works with a W-shaped clamping system in universal holders, enabling multiple operations—minimises setup changes, slashes cycle time, boosts stability.

🏭 Applications

-

Automotive — precision internal grooves on shafts and components

-

Aerospace — tight-tolerance grooves in stainless steel parts

-

Die & Mold — clean, intricate slotting in hardened materials

-

General Engineering — high-wear resistance for demanding grooving tasks

📞 Order Now

Related Products

You May Also Like

Frequently Asked Questions

It’s ideal for stainless steel and difficult-to-machine materials, thanks to its PC9030 grade CVD coating and tough substrate.

The insert has a 1.5 mm cutting width, 0.15 mm corner radius, 1.2 mm groove width (d), 3.5 mm thickness (t), and approximately 16 mm length.

Designed to form narrower chips, it improves chip evacuation, reduces clogging, and enhances machining stability.

Its compatibility with the MGT system’s holders means you can groove, turn, face, and copy with one toolholder—reducing tool changes, increasing uptime, and simplifying setup.

Widely used in automotive, aerospace, die & mold, and general engineering sectors where precision grooving and high wear resistance are essential.