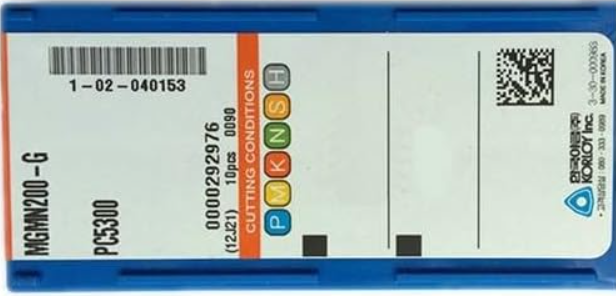

Korloy MGMN150-G CN1500

Korloy MGMN150-G CN1500 carbide insert delivers longer tool life, superior wear resistance, and smooth surface finish — the ideal choice for high-speed steel and alloy machining in automotive, aerospace, die-mold and general engineering.

Longer tool life. Faster cycles. Lower cost per component. — Upgrade your grooving & turning operations with Korloy MGMN150-G CN1500 from CNC Tools Depot.

Hook / Attention Line

Still Changing Inserts Too Often? Switch to CN1500 & Cut Your Downtime in Half.”

Key Features & Specs

-

Geometry / Insert Type: MGMN150-G (grooving / narrow-width insert from Korloy’s MGMN-G series) — designed for precision grooving, turning and small-width cut operations.

Grade: CN1500 — a high-performance coated cermet grade optimized for continuous high-speed turning and grooving of carbon steel and alloy steel. -

Coating / Substrate: High-quality coated cermet (micro-grain substrate + wear-resistant coating), engineered for high resistance against chipping and thermal cracking.

Applications: Precision grooving, narrow-width cuts, turning & grooving on steel, alloy steel, cast iron — even small-section components and continuous machining

Why It’s a Best Seller

-

Reduced downtime & lower tooling cost — The CN1500 grade’s superior wear and chipping resistance means fewer insert changes and longer runtimes.

-

Better surface finish — Optimized cutting-edge geometry delivers smoother finishes and reduces surface roughness, even in continuous cuts.

-

High stability & consistency — Uniform micro-grain substrate minimizes thermal cracking and provides stable performance across long runs.

-

Versatile & reliable — Suitable for a wide range of steels, making it a go-to in varied production settings from small components to heavy part grooving.

🏭 Application Industries

Automotive, Aerospace, Die & Mold, General Engineering — especially where precision grooving, narrow-width features or continuous steel turning is required.

Related Products

You May Also Like

Frequently Asked Questions

It is ideal for carbon steel, alloy steel, cast steel — basically steels where high-speed grooving/turning is required. The CN1500 grade is engineered for continuous machining of steel and alloy steel.

Yes — CN1500 is designed for continuous high-speed machining and produces excellent surface finish. Its micro-grain cermet substrate resists chipping and thermal crack, delivering stable, long-life performance.

Compared to conventional carbide, CN1500’s uniform micro-grain substrate and optimized coating significantly improve wear resistance, reduce thermal cracking and chipping, and ensure better surface finish and longer runtime.

Absolutely. Its stability under continuous cutting, resistance to wear and chipping and consistent surface finish — make it ideal for high-volume machining in automotive, die-mold, aerospace and general engineering setups.

Simply send us a DM, WhatsApp or call at CNC Tools Depot — we will check stock levels, provide bulk-order pricing, and deliver directly to your shop.