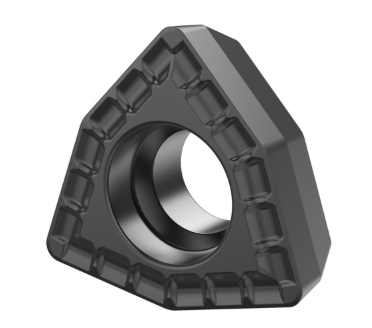

Union TNGA 160408 ST300

Union TNGA 160408 ST300 is a premium, uncoated carbide turning insert designed for stable machining of steels and alloy steels. Excellent edge toughness, wear resistance, and reliability in medium to finish turning.

The ST300 grade is built for consistent performance in general steel and alloy steel machining, offering the durability needed for continuous cutting with reduced insert wear. Its TNGA geometry (negative, double-sided, strong insert shape) delivers high edge strength and reduces vibration—ideal for stable turning applications.

Hook / Attention Line

Boost your turning performance with the Union TNGA 160408 ST300 — engineered for precision, stability, and long tool life.

Key Features & Specs

-

Insert Type: TNGA 160408

-

Turning Geometry: Robust negative geometry for stability & rigidity

-

Grade: ST300 – suitable for steel & alloy steel turning

-

Coating: Uncoated carbide (recommended for predictable, stable cutting conditions)

-

Cutting Applications:

-

Medium turning

-

Semi-finishing

-

Continuous & light interrupted cuts

-

-

Performance Benefits:

-

High edge toughness for stable machining

-

Reliable wear resistance

-

Strong insert structure for longer tool life

-

Improved dimensional accuracy & surface finish

-

Why It’s a Best Seller

-

Minimizes insert breakage due to strong geometry

-

Reduces downtime with longer, predictable tool life

-

Provides cleaner surface finish in medium turning

-

Ideal for mass production environments needing consistency

🏭 Application Industries

-

Automotive component machining

-

General engineering workshops

-

Heavy machinery parts

-

Fabrication units

-

Steel & alloy steel component production

You May Also Like

Frequently Asked Questions

It is designed for steel and alloy steel turning, especially in medium and semi-finish operations.

No, it is uncoated, which helps deliver consistent, predictable cutting performance in stable conditions.

TNGA inserts offer high edge strength, double-sided usability, and excellent stability during turning.

Yes, it performs well in continuous to light interrupted cutting conditions.

Yes! CNC Tools Depot provides special pricing for bulk buyers. Contact us via DM or WhatsApp to get a quote.