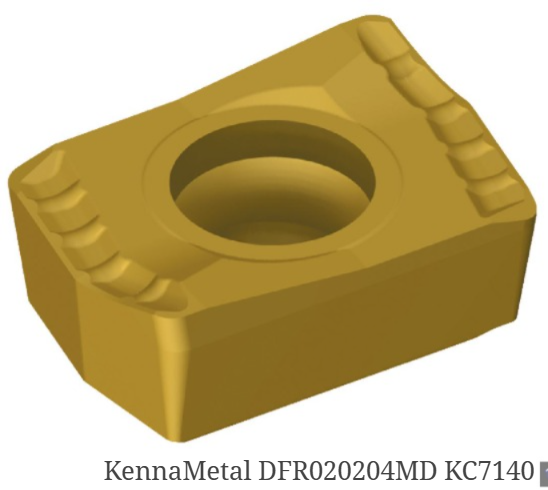

KennaMetal DFT06T308MD KCU40

Kennametal DFT06T308MD KCU40 is a CVD-coated carbide milling insert engineered for stable cutting, extended tool life, and consistent performance in steel and cast iron machining applications.

The Kennametal DFT06T308MD KCU40 carbide insert is engineered to deliver reliable and repeatable milling performance in demanding production environments. Featuring the DFT insert geometry, it ensures excellent cutting stability and controlled chip formation, helping machinists maintain consistent results across a wide range of machining conditions.

Hook / Attention Line

“Stable milling. Longer tool life. Lower cost per part.

Key Features & Specs

✅ Insert Geometry: DFT – Designed for stable milling with smooth chip evacuation

✅ Grade: KCU40 – Versatile CVD-coated carbide grade

✅ Coating: Multi-layer CVD coating for enhanced wear resistance

✅ Applications: Primarily milling operations in steel and cast iron

✅ Performance Focus: Balanced toughness + wear resistance for longer tool life

Why It’s a Best Seller

⭐ Reduces unexpected tool failures

⭐ Delivers consistent performance across varying cutting conditions

⭐ Helps lower cost per component with predictable insert life

⭐ Ideal for both roughing and semi-finishing applications

🏭 Application Industries

🏭 Automotive

✈️ Aerospace

🛠️ Die & Mold

⚙️ General Engineering & Job Shops

You May Also Like

Frequently Asked Questions

It is mainly used for milling operations, especially in steel and cast iron materials.

KCU40 offers a balanced combination of wear resistance and toughness, making it suitable for a wide range of milling conditions.

Yes, its stable cutting performance and predictable tool life make it ideal for production and batch machining.

Automotive, aerospace, die & mold, and general engineering industries frequently use this grade and geometry.

You can buy 100% genuine inserts from CNC Tools Depot. Contact via WhatsApp, Call, or DM to check current pricing and availability.