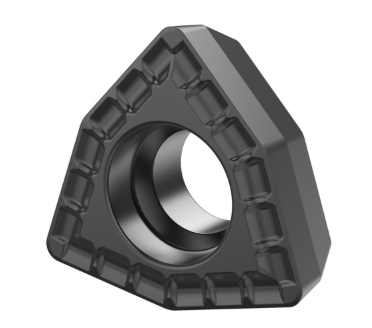

KennaMetal DFT06T308MD KCU25

Boost productivity with Kennametal DFT06T308MD KCU25 — rugged PVD-coated carbide drill insert delivering longer tool life, reduced downtime, and excellent performance on steel & stainless steel. DM or WhatsApp us today for price & stock! #CarbideInserts #CNCTools #Kennametal #CNCmachining

🚀 Cut costs per part — go longer, faster, smoother.

The Kennametal DFT06T308MD KCU25 is engineered to deliver robust performance in demanding drilling operations. With a 10 mm inscribed circle (IC), 3.75 mm thickness and trigon (84°) geometry, this indexable drill insert is built for precision and endurance.

Hook / Attention Line

🚀 Cut costs per part — go longer, faster, smoother.

Key Features & Specs

-

Geometry / Style: DFT — 84° trigon drill insert, 10 mm IC, 6.62 mm cutting edge length, 3.75 mm thickness.

-

Corner Radius: ~0.8 mm.

-

Coating & Grade: PVD-coated carbide with Kennametal Grade KCU25 — fine-grain substrate + hard AlTiN (or equivalent) coating for high edge stability.

-

Material Compatibility: Optimized for steel and stainless steel — including low-carbon steels, alloy steels and many commonly used grades.

-

Cutting Applications: Drilling (indexable drill application). While this is primarily a drill insert, the carbide + geometry can serve well in operations requiring stable, hard-wearing carbide performance.

Why It’s a Best Seller

-

✅ High wear resistance & long tool life: Thanks to fine-grain carbide substrate + robust PVD coating, the insert stands up to repeated drilling — reducing frequent tool changes.

-

✅ Reduced downtime: With stable edge retention and consistent performance, shops spend less time changing inserts and more time running production.

-

✅ Reliable performance on steels / stainless / common alloys: KCU25’s versatility ensures you don’t need multiple grades for common materials — a single insert covers many jobs.

-

✅ Better consistency & surface finish: Stable geometry and cutting edge deliver clean, repeatable holes — improving part quality and reducing scrap or rework.

🏭 Application Industries

-

Automotive machining (engine blocks, components, shafts)

-

Aerospace components (steel or stainless parts drilling)

-

Die & mould industry — for jigs, fixtures, steel mold bases

-

General engineering — shafts, housings, fabrications needing reliable drilling in steel or stainless

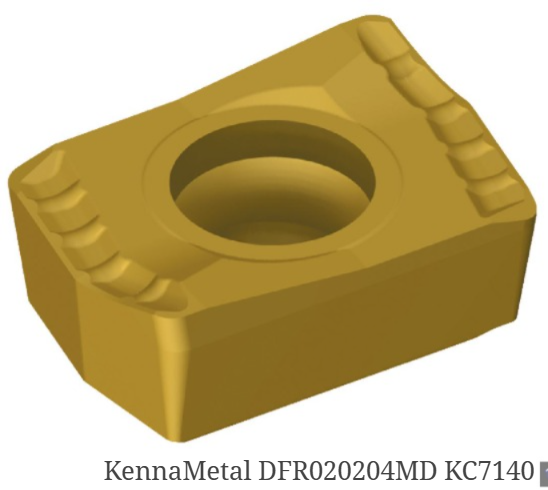

You May Also Like

Frequently Asked Questions

It’s suitable for steel and stainless steel — ranging from low-carbon to many alloy grades

It has a 10 mm inscribed circle (IC), 3.75 mm thickness, 84° trigon geometry, and ~0.8 mm corner radius.

KCU25 is a PVD-coated fine-grain carbide grade with high edge toughness and stable performance across a wide speed/feed range, giving excellent wear resistance and long tool life.

It’s designed for indexable drilling (holemaking) — ideal where precision holes in steel or stainless steel are required.

Industries such as automotive, aerospace, die & mould, general engineering — anywhere you need reliable drilling of steel or stainless-steel components with minimal downtime and consistent quality.