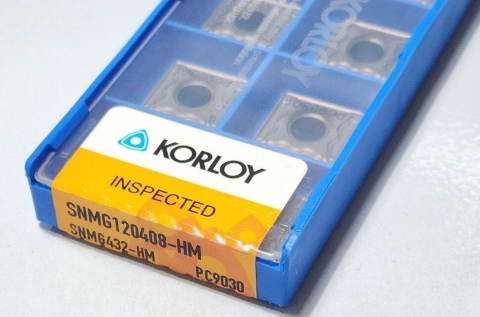

Korloy SNMG120408-HA PC9030

Korloy SNMG 120408 HA PC9030 — 90° square carbide insert (12 mm IC, 4 mm thickness) with PVD/CVD coating, designed for stainless-steel turning & semi-heavy duty cutting. Popular choice for long tool life, reliable chip control, and high surface finish.

Upgrade your turning performance with the Korloy SNMG 120408 HA PC9030, a premium square-shaped carbide insert engineered for consistent accuracy, long tool life, and stable machining even under demanding conditions. Designed with Korloy’s advanced coating technology and precision-ground geometry, this insert is a proven performer for stainless-steel and alloy-steel turning across high-volume production environments.

Hook / Attention Line

Boost your productivity & cut tooling cost per part — with longer tool life, smoother cuts, and less downtime using the SNMG 120408 HA PC9030.

Key Features & Specs

-

Geometry & Size: SNMG 120408 — 90° square insert, inscribed circle (IC) 12 mm, thickness ~4 mm.

-

Corner Radius: Typically 0.8 mm (common for “08” in designation).

-

Grade & Coating: PC9030 — carbide substrate with PVD / CVD coating optimized for high-temperature and wear resistance.

-

Cutting Applications: Best for external turning — ideal for semi-finishing to heavy interrupted turning on stainless steel, steels, cast iron, and similar materials.

Why It’s a Best Seller

-

Exceptional wear resistance and heat tolerance, giving longer life per insert even under heavy or interrupted cuts. Less frequent insert change = lower downtime and more productivity.

-

Produces better surface finish & stable cuts, thanks to optimized geometry & coating for stainless steel or difficult materials. Smooth chip flow and reliable performance even under demanding conditions.

-

Cost-efficient & versatile — one insert works across multiple materials and part types (roughing, semi-finishing to finishing), making it ideal for varied production runs without frequent tool changes.

🏭 Application Industries

-

Automotive (shafts, hubs, components in stainless steel or alloy steel)

-

Aerospace & Defence (precision parts, stainless or alloy components)

-

Die & Mold making (stainless, alloy steels, cast iron components)

-

General Engineering & Fabrication (shafts, flanges, components requiring consistent finish & long tool life)

Related Products

You May Also Like

Frequently Asked Questions

It’s optimized for stainless steel, alloy steel, cast iron, but versatile enough for general-purpose turning on steel and similar metals

Primarily semi-finishing to finishing and heavy or interrupted turning operations. It gives good stability under tough cuts, yet produces clean finishes.

SNMG 120408 — 90° square insert, 12 mm inscribed circle (IC), approx. 4 mm thickness, with typical corner radius around 0.8 mm.

PC9030 offers superior wear resistance, heat resistance, and oxidation resistance under high-temperature cutting — meaning longer tool life, fewer changes, and consistent performance on stainless or alloy steels.

Ideal for automotive parts, aerospace components, mold & die work, general engineering — anywhere stainless steel or alloy steel turning with a need for high tool life, consistent finish, and cost-effective production.