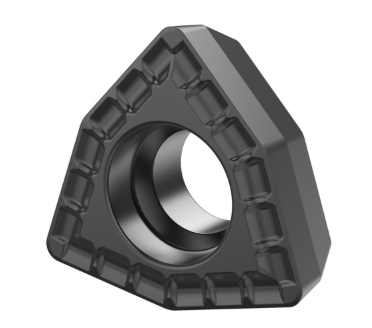

Kennametal TNGX1905PNTR KCPK30

Boost productivity with the Kennametal TNGX1905PNTR KCPK30 insert—a robust, CVD-coated carbide insert engineered for heavy-duty turning and milling of steels, cast irons, and high-temp alloys. Ideal for automotive, aerospace, die & mold, and general engineering. High wear resistance and long tool life. Contact CNC Tools Depot via DM, WhatsApp, or Call for pricing and bulk availability.

Unleash the true potential of your CNC machining with the Kennametal TNGX1905PNTR KCPK30 insert—designed for durability, efficiency, and smoother production.

MEANING

-

Geometry & Configuration

The TNGX1905PNTR insert, part of the TNG family, is a pressed-to-size design optimized for turning and compatible with select shoulder milling systems like ECO SIX cutters ScribdTITANS of CNC. -

Material Grade & Coating

Coated with a CVD multi-layer system (TiN/TiCN/Al₂O₃) and polished via Beyond™ post-coat treatment, the KCPK30 grade combines superior wear resistance with excellent toughness—ideal for general purpose and heavy roughing in steels and cast irons. Best performance is achieved in dry machining, although wet cutting is also supported

Applications

Applications (Turning, Milling, Drilling)

While TNGX1905PNTR is primarily for turning, it’s also used effectively in ECO SIX shoulder milling systems, achieving improved velocities and feed rates with reduced cycle times and tool change frequency

Why It’s a Best Seller

-

Why It’s a Best Seller

-

Up to 20% longer tool life and 30% faster cycle times in real-world applications (e.g., face and shoulder milling of grey cast iron under dry cutting) Scribd.

-

Reduced downtime—fewer tool changes thanks to extended edge life and multi-edge design.

-

Superior surface finish—Beyond™ coating delivers uniform wear, micro-polished edges, and less chipping Productivity Inc.

-

High wear resistance—CVD coating ensures durability even under demanding conditions.

-

-

Ideal Industries

Automotive | Aerospace | Die & Mold | General Engineering | Heavy Equipment Manufacturing

Benefits Summary

Benefits Summary

-

Lower cost per part, thanks to longer wear life and fewer insert changes

-

Increased throughput with faster feeds & speeds

-

Exceptional surface finish and consistency

-

Dry machining capability reduces coolant usage and overhead

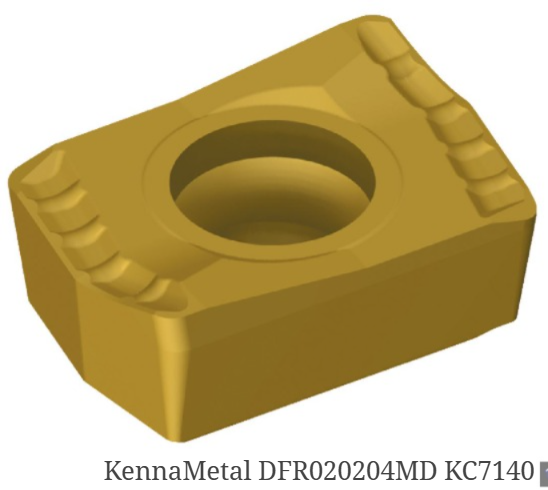

You May Also Like

Frequently Asked Questions

It uses the KCPK30 grade, with a CVD multi-layer coating of TiN/TiCN/Al₂O₃ and Beyond™ post-coat treatment, offering high wear resistance and edge toughness

Ideal for steels, stainless steels, cast irons, and even high-temperature alloys. Perform best in dry cutting, but can also be used wet

In ECO SIX shoulder milling tests, users achieved 20% longer tool life and 30% faster cycle times—boosting output while lowering per-part cost

Mainly designed for turning, but also highly effective in ECO SIX shoulder milling setups when paired with the right cutter bodies

Perfect for precision and heavy-duty machining in automotive, aerospace, die & mold, general engineering, and large-scale fabrication.