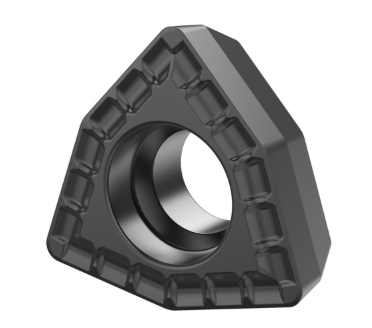

Kennametal APMT1604PDR K00035

High-performance Kennametal APMT1604PDR K00035 carbide insert. Optimised geometry + premium grade + K00035 coating. Ideal for milling in steel, stainless, high-hardness materials. Less downtime, better surface finish. Available now at CNC Tools Depot.

Unlock higher productivity with the Kennametal APMT1604PDR K00035

At CNC Tools Depot, we’re proud to present the Kennametal APMT1604PDR K00035 – a benchmark carbide insert built for serious machining operations. With its engineered geometry, premium grade and advanced coating, you can expect longer tool life, faster cutting and lower cost per part.

Key Features & Specifications:

-

Insert type: ISO-parallelogram, family APMT1604PDR (typically ~16 mm cutting edge length)

Grade: Kennametal’s premium grade compatible with tough applications (note: the datasheet for APMT1604PDR cites grade WU20PM in one source)

Corner radius: approx R 0.8 mm (0.031 in) for general purpose milling and good edge strength. -

Coating: K00035 – specialised coating for extended wear resistance across steels, stainless steels and high-hardness materials.

-

Applications: Designed for shoulder milling, face milling, pocketing, ramping, plunging operations in milling tool-holders (common D30‐D40 tool bodies)

Multi‐material capability: Excellent for carbon steel, alloy steel, stainless steel, high-hardness (> HRC) work-pieces thanks to the advanced coating and chipbreaker design.

Why It’s a Best Seller:

-

Minimises downtime: The durable grade + coating combination means fewer insert changes and more uninterrupted production time.

-

Superior surface finish: The controlled geometry and premium coating give consistent finish results even in tougher materials.

-

High wear resistance: The K00035 coating is designed to resist wear and edge chipping, extending insert life and reducing cost per component.

-

Broad versatility: One insert works across multiple materials and operations, simplifying inventory and tool-management.

Application Industries:

Ideal for heavy-duty and precision-critical sectors including:

-

Automotive: engine components, transmission parts, structural components

-

Aerospace: air-frame components, high-temperature alloys (with appropriate cutting data)

-

Die & mould: tool steel, stainless mould blocks, complex cavity milling

-

General engineering: heavy fabrication, structural parts, high-volume milling of steel and stainless

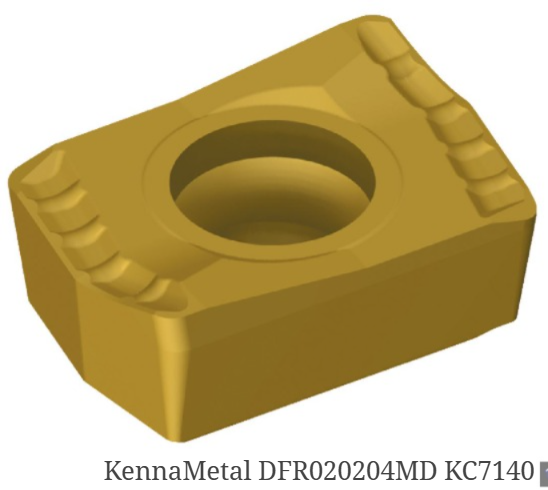

You May Also Like

Frequently Asked Questions

“APMT1604PDR” is the insert designation – ISO APMT format, 16 mm edge length (~), and “PDR” indicates the chipbreaker/geometry variant. “K00035” is the coating or finish code from Kennametal. Together, they define a specific version optimised for multi-material milling.

It is equipped to machine medium to high-hardness steels, stainless steels and other demanding materials thanks to the K00035 coating and strong geometry. According to sources, it is suitable for carbon steel, stainless steel, high-hardness work-pieces.

Ideal for shoulder milling, face milling, pocketing, ramping and plunging in milling tool-holders (e.g., D30, D32, D35, D40 shank sizes) as noted in distributor description.

The corner radius is approx R 0.8 mm (0.031 in) which gives good edge strength while still providing flexibility for finishing operations – a good balance of durability + finish quality

Because you get access to a best-in-class insert from an industry leader (Kennametal) via India’s largest dedicated marketplace for carbide inserts. It means reliable supply, true spec parts, expert support and the potential for bulk savings. Combined with the performance benefits (less downtime, longer life, better finish), it’s a smart choice for serious manufacturers.