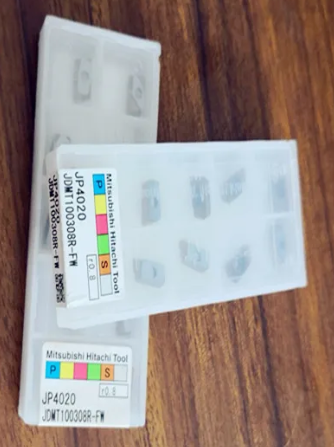

Hitachi WDNW 09T320 JP4020

The Hitachi WDNW09T320 JP4020 is a robust 80°-diamond (W-shape) carbide insert, designed for hardened steel, cast iron and stainless applications. With the JP4020 grade and PVD/CVD coating, it delivers higher wear resistance, better surface finish and lower cost-per-part. Ideal for turning and milling in automotive, aerospace, die & mould and general engineering. Available at CNC Tools Depot – DM or WhatsApp for stock and bulk pricing.

The Hitachi WDNW09T320 JP4020 carbide insert is engineered for machinists who demand maximum tool life, stable performance and reduced cost-per-component—especially when working with challenging materials. Built with Hitachi’s trusted JP-series cutting-grade technology, this insert delivers the perfect blend of wear resistance, edge stability and thermal toughness, making it a top-choice for high-precision industries across India.

Hook / Attention Line

Meet the Hitachi WDNW09T320 JP4020 – engineered for high-performance machining with real cost savings.

Key Features & Specs

-

Get longer tool life and fewer insert changes – which means less downtime and higher productivity.

-

Achieve faster cutting or more stable feeds even on tougher materials, lowering the cost per component.

-

Produce better surface finish and dimensional consistency thanks to the high-quality grade and geometry.

-

Insert code: WDNW09T320 with grade JP4020 (Hitachi/Moldino) – targeted at hardened steel (≈ 40–55 HRC), cast iron, stainless and general engineering materials.

-

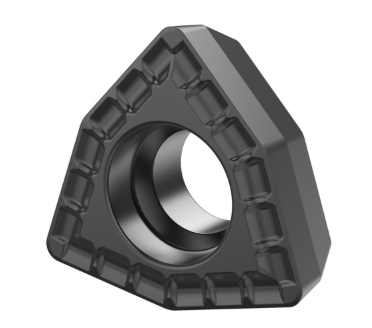

Geometry: W-shape (80° diamond style) indicated by the “WDNW” series; allows strong edge and stable turning/milling performance.

-

Insert size: Approx. 9.525 mm inscribed circle, thickness ~3.97 mm; corner radius typically ~2.0 mm for this variant.

-

Coating / grade: JP4020 grade from Hitachi signifies high-performance coated carbide for more demanding work-piece materials.

-

Applications: Ideal for turning, milling, even drilling/roughing when the toolholder supports the geometry; especially effective on hardened steel, cast iron and tough alloys.

Why It’s a Best Seller

-

Because it lets machinists run longer between changes – fewer insert swaps, less setup time.

-

Because it gives consistent surface finish and less scrap – your parts meet spec more reliably, rework drops.

-

Because it holds up better under wear, especially when working hardened or interrupted cuts – giving you high wear resistance and therefore lower cost-per‐part.

🏭 Application Industries

-

Automotive: engine blocks, housings, high-hardness transmission components.

-

Aerospace: structural steel parts, hardened housings, cast components.

-

Die & Mould: high-hardness steels, cast stainless dies.

-

General Engineering: cast iron components, stainless assemblies, high-volume production runs.

You May Also Like

Frequently Asked Questions

The JP4020 grade is targeted at tougher work-piece materials including hardened steels (in the ~40-55 HRC range), cast iron and stainless steels.

The “WDNW” family indicates an 80° diamond-shaped insert (W-shape). The W shape allows a strong cutting edge for higher stability and versatility in turning or milling operations, making it ideal for interrupted and tougher cuts

For the WDNW09T320 variant: inscribed circle ~9.525 mm; thickness ~3.97 mm; corner radius around 2 mm.

Because with the JP4020 grade you benefit from higher wear resistance, fewer insert changes, better surface finishes and less downtime – which lowers your cost per component and improves throughput.

Simply DM us your requirement, or WhatsApp/call us with the part number (WDNW09T320 JP4020), quantity and machine application. We’ll check real-time stock, provide pricing (including bulk), and arrange delivery to your location in India.