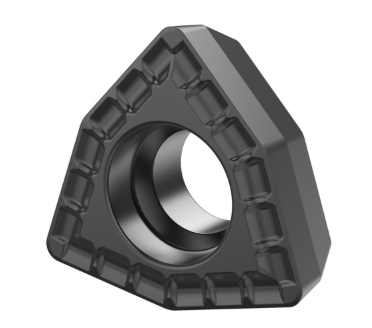

Ceratizit CCMT 09T308 EN-F43 CTC 2135

Ceratizit CCMT 09T308 EN-F43 CTC2135 is a premium carbide turning insert with rounded 0.8 mm corner radius, TiCN+TiNB coating, built for longer tool life, excellent surface finish and reliable performance in steel & general engineering applications.

The Ceratizit CCMT 09T308 EN-F43 CTC2135 insert is engineered for precision turning tasks where wear resistance, surface finish, and reduced downtime are critical. Featuring the CCMT-09T308EN geometry (80° rhombic shape, neutral hand), a rounded 0.8 mm corner radius, and thickness of approx. 3.97 mm, this insert is designed to offer strength at the cutting edge and resistance to chipping under moderate to heavy feeds.

Its grade CTC2135 with TiCN + TiNB coating enhances hard-phase wear resistance and improves life even under interrupting cuts or variable cutting conditions. The F43 chip breaker favours stable chip control, helping to maintain surface finish and reduce burrs.

Perfect for steel & general engineering, die & mold pre-finishing, as well as automotive component turning. Whether you run batch work or continuous production, expect fewer tool changes, higher throughput, and better cost per part.

Hook / Attention Line

Cut more parts. Less downtime. Drastically reduce your cost per component with the Ceratizit CCMT 09T308 EN-F43 CTC2135 – built for high wear resistance and excellent finish.”

Key Features & Specs

-

Geometry: CCMT-09T308EN, rhombic (80° insert), neutral hand, corner radius (RE) 0.8 mm.

-

Grade & Coating: CTC2135 grade with TiCN + TiNB coating – designed to resist wear and provide good toughness.

-

Insert Thickness / Size: Inscribed circle ~9.52 mm, thickness ~3.97 mm.

-

Chipbreaker & Clearance: Equipped with F43 chip breaker, rounded cutting edge, with major clearance angle ~7°.

-

Cutting Applications: Optimized for turning operations; suitable for steel, general engineering materials, possibly light to medium finish turning

Why It’s a Best Seller

-

Delivers high wear resistance so inserts last longer – fewer change-overs, more uptime.

-

The TiCN + TiNB coating gives a smoother surface finish, reducing need for secondary finishing.

-

Rounded corner radius (0.8 mm) improves strength at the cutting edge under moderate feeds, reducing chipping.

-

Balanced geometry + grade helps you push cut parameters a bit more without sacrificing life – lowering cost per part.

Industry / Application

Used widely in:

-

Automotive (shafts, housings, components)

-

General engineering & fabrication

-

Die & mold (pre-machining, semi-finishing)

-

Heavy equipment maintenance & repair

Call-to-Action:

You May Also Like

Frequently Asked Questions

Ideal for steel (medium hardness), general engineering materials. It performs well in components where wear resistance and surface finish are important. For very hard materials or abrasive cast irons, other specialized grades may be more suitable.

This insert comes with a 0.8 mm corner radius, giving a good balance: strong cutting edge (less chance of chipping) and decent surface finish. If you need ultra-fine finishes, a smaller radius may help, but expect reduced robustness.

Yes. Even though the chip breaker & geometry are optimized, using coolant or effective lubrication will help extend tool life, especially in heavier cuts or interrupted cuts.

The TiCN+TiNB coating in CTC2135 greatly improves wear resistance and helps maintain sharpness under load. Compared to uncoated or single-layer inserts, you’ll see longer life, better finish, and better stability under varied conditions.

Typically these CCMT inserts are two-indexed (you can rotate to use the other cutting edge), so you get two usable edges per insert, doubling your effective usage compared to single-edge inserts (given similar wear and cutting conditions).