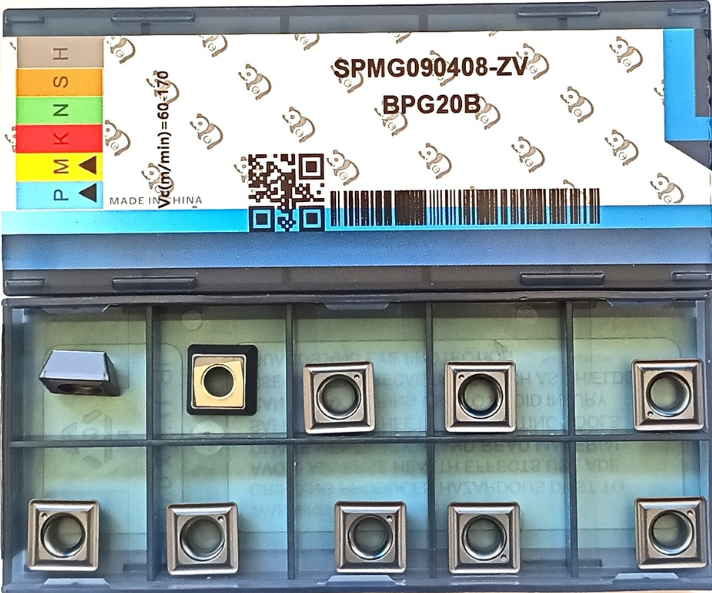

TDC2 BPG 20B

Achieve exceptional edge strength and surface finish with TDC2 BPG20B PVD-coated carbide inserts—engineered for stainless steel finishing at moderate speeds and light interrupted cuts.

TDC2 BPG20B carbide inserts combine robust geometry with advanced micro-grain carbide and PVD coating to deliver:

-

Geometry & Chip Control: TDC2 double-ended grooving geometry with a precision chip-breaker ensures stable, efficient grooving and parting operations.

-

Grade & Coating: BPG20B is a PVD-coated, micro-grain carbide specially formulated for stainless steel applications. It offers superior edge strength and thermal shock resistance for demanding machining conditions BFL Tool.

-

Cutting Applications: Ideal for stainless steel finishing, especially at medium to low cutting speeds and for light interrupted cuts—delivering excellent surface quality and reliability

Lead-Generation

Lead-Generation Push

Send us a WhatsApp right now to check today’s price & availability!

Hook

Hook / Attention Line

“Maximise your uptime and surface finish—TDC2 BPG20B delivers longer life with razor-sharp edges for spotless stainless finishes.”

Key Features

Key Features & Specs

-

Geometry: TDC2 double-ended grooving design with optimized chip-breaker for consistent, reliable cuts.

-

Grade & Coating: PVD-coated micro-grain carbide (BPG20B) engineered for stainless-steel finishing; excellent edge strength and high thermal-shock resistance BFL Tool.

-

Applications: Grooving & parting of stainless steel at moderate to low speeds, including light interrupted cuts.

Why It’s a Best Seller

Why It’s a Best Seller

Its PVD coating and fine carbide base deliver outstanding wear resistance and edge stability—resulting in less tool change downtime, smoother finishes, and lower cost per component. That means fewer interruptions and consistently superior part quality.

Industries

Industries Benefiting Most

-

Automotive

-

Aerospace

-

Die & Mold

-

General Engineering

You May Also Like

Frequently Asked Questions

It’s optimized for finishing stainless steels at medium-low speeds and even light interrupted cuts, delivering excellent surface quality.

– A PVD-coating on micro-grain carbide gives it superior edge strength and resistance to thermal shock, making it long-lasting under tough cutting conditions

Perfect for grooving and parting operations, especially where precision and minimal downtime are critical.

Fewer insert changes = more uptime. Plus, it consistently delivers high surface quality and reduces cost per component.

Drop us a DM, WhatsApp, or call CNC Tools Depot—our team will assist with stock, pricing, and bulk-order terms right away.