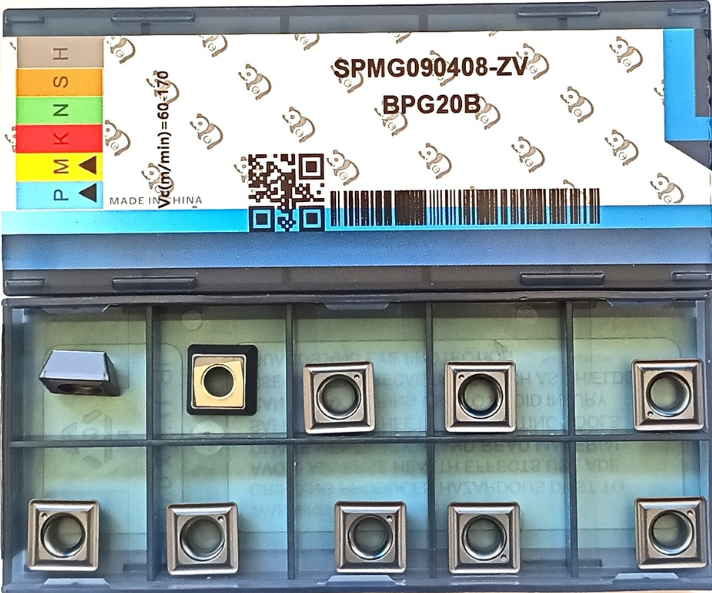

CDBP TDC-3 BPG20B

The TDC 3 BPG20B CDBP carbide insert is engineered for high-precision grooving and parting operations on steel and stainless steel. Its advanced geometry and coating deliver superior wear resistance and surface finish.

The TDC 3 BPG20B CDBP carbide insert is a premium cutting tool designed for demanding grooving and parting applications in steel and stainless steel. Manufactured by CDBP, this insert features a double-ended design with a C-type chip breaker, ensuring stable cutting edges and efficient chip control. The PVD coating enhances wear resistance, extending tool life and maintaining consistent performance. Ideal for industries requiring high precision and reliability, such as automotive and general engineering.

Key Features & Specifications:

-

Geometry: 3 BPG20B – Double-ended insert with a C-type chip breaker for efficient chip control.

-

Grade: CDBP – Universal grade suitable for a wide range of materials.

-

Coating: PVD coating for enhanced wear resistance and extended tool life.

-

Cutting Applications: Ideal for grooving and parting operations on steel and stainless steel.

Why It’s a Best Seller:

The TDC 3 BPG20B CDBP insert is renowned for its durability and performance. The double-ended design allows for extended tool life, while the C-type chip breaker ensures smooth chip flow and reduces cutting forces. The PVD coating provides additional wear resistance, making it a cost-effective choice for high-volume machining operations.

Application Industries:

-

Automotive: Precision machining of components for engines and transmissions.

-

General Engineering: Versatile applications in various machining tasks requiring reliable tool performance.

📞 Call-to-Action:

You May Also Like

Frequently Asked Questions

This insert is designed for grooving and parting operations on steel and stainless steel.

The PVD coating enhances wear resistance, extending tool life and maintaining consistent performance.

While primarily designed for grooving and parting, it may be suitable for light turning operations depending on the specific application

The double-ended design and PVD coating contribute to an extended tool life, reducing the frequency of insert changes.

Compatibility depends on the specific machine and tool holder. It's recommended to consult with CNC Tools Depot for compatibility verification.