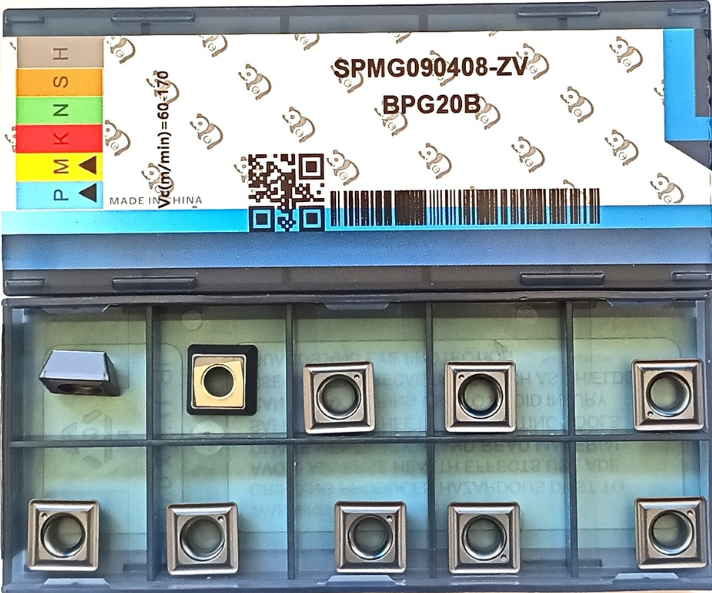

CDBP SPMG 110408-ZV BPG20B

The CDBP SPMG 110408-ZV BPG20B is a premium carbide insert engineered for high-performance machining — offering extended tool life, excellent wear resistance, and superior finish in turning, milling and drilling applications. Ideal across automotive, aerospace, die & mold and general engineering. DM or WhatsApp us to check today’s prices.

Boost Productivity and Cut Costs with CDBP SPMG 110408-ZV BPG20B Carbide Inserts

When every minute counts on the shop floor, the CDBP SPMG 110408-ZV BPG20B carbide insert delivers the performance your machines deserve. Designed for precision, durability, and speed, this insert is a trusted choice for manufacturers aiming to achieve faster machining cycles, superior surface finish, and longer tool life.

Hook / Attention Line

Cut more parts. Change inserts less often. With the CDBP SPMG 110408-ZV BPG20B insert you get longer tool life, faster cuts and a lower cost per component — exactly what your shop needs.

Key Features & Specs

-

Geometry / Design: SPMG 110408-ZV form (designed for indexable U-drill / milling / turning style holders). Known for good chip control and stability.

-

Grade & Coating: ZV chipbreaker with grade BPG20B — offers a balanced combination of toughness and wear resistance.

-

Materials & Applications: Built to handle carbon steel, alloy steel, cast iron, and moderate stainless steels. (Several sources list it as “suitable for carbon steel, alloy steel, cast iron, hardened steel” when used correctly)

-

Cutting Modes: Highly versatile — use in turning, milling, and drilling/U-drill operations depending on your holder setup and machine.

-

Coating / Surface Treatment: PVD or similar high-quality wear-resistant coatings that reduce friction and help resist built-up edge under demanding conditions.

Why It’s a Best Seller

-

Less Downtime: The robust BPG20B grade and optimized geometry let you run longer between insert changes.

-

Consistent Surface Finish: Excellent stability and chip control help you hit finish targets reliably.

-

High Wear Resistance: The coating and carbide substrate handle abrasion, edge stress and heat — so the insert stays sharper longer.

-

Broad Suitability: Works well across a variety of materials and operations, helping reduce your tooling SKUs.

🏭 Application Industries

This insert finds frequent use in:

-

Automotive & engine component manufacturing

-

Aerospace (structural parts, housings)

-

Die & mold making (milling and finishing)

-

General engineering and job shops machining steel, cast iron, and alloy parts

📞 Call-to-Action

You May Also Like

Frequently Asked Questions

You can use the SPMG 110408-ZV BPG20B in turning, milling and drilling (especially in U‐drill style setups) depending on your tooling setup.

It’s designed to perform well on carbon steel, alloy steel, cast iron, and certain stainless steels.

The BPG20B grade offers a good balance between toughness and wear resistance, making it reliable in mixed production environments where you encounter both moderate stresses and abrasive conditions.

Because it offers long tool life, consistent finish, and versatility across operations — lowering your cost per part and simplifying inventory.

You can DM or WhatsApp us or call us for pricing, stock and bulk order. Lead time typically depends on stock levels; we’ll confirm back immediately when you reach out.