Login / Register

Verify OTP

Update Profile

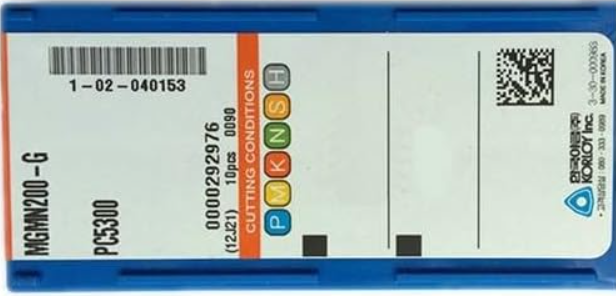

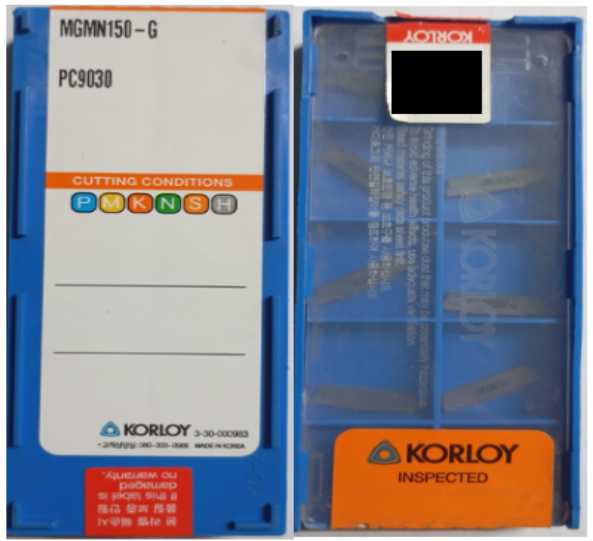

Korloy MGMN200-M H01

Get the MGMN 200-M H01 grooving insert – optimized for high-speed machining of aluminum and non-ferrous materials. Known for sharp cutting edges, excellent chip control, and consistent finish, it’s a favorite across automotive, aerospace, and general engineering industries.

⚡ Achieve Mirror-Finish Grooving in Aluminum & Non-Ferrous Metals!

CNC Tools Depot brings you the MGMN 200-M H01, a high-precision grooving insert trusted by machinists for unbeatable accuracy and tool life.

Key Features & Specs

✔ Geometry: M-type chipbreaker for stable grooving and chip evacuation

✔ Grade: H01 – uncoated, fine-grain carbide for aluminum & non-ferrous machining

✔ Edge Sharpness: Designed for reduced cutting resistance & superior surface finish

✔ Applications: Ideal for grooving & parting operations in CNC turning

🚀 Why It’s a Best Seller:

-

Longer tool life → fewer insert changes, less downtime

-

Mirror-like finish on aluminum & non-ferrous parts

-

Excellent chip control → no tangled swarf, smoother operations

-

High cutting reliability → consistent performance in production

🏭 Application Industries:

-

Automotive components

-

Aerospace parts

-

Die & mold manufacturing

-

General precision engineering

CALL -TO-ACTION

Related Products

You May Also Like

Frequently Asked Questions

It’s a grooving insert designed for machining aluminum and non-ferrous materials with high precision and superior surface finish.

H01 is an uncoated, fine-grain carbide grade that delivers sharp cutting edges, minimal built-up edge, and longer tool life in aluminum and non-ferrous applications.

No – this insert is specifically designed for aluminum and non-ferrous materials. For steel, other coated grades are recommended.

They are widely used in automotive, aerospace, die & mold, and general engineering industries where precision grooves and surface finish are critical.

You can DM us, call, or send a WhatsApp message to check stock, pricing, and bulk order availability.

© 2026. All Rights Reserved

Disclaimer: All Brand Logos belong to their respective owners, CNC Tools Depot is sharing publicly available information