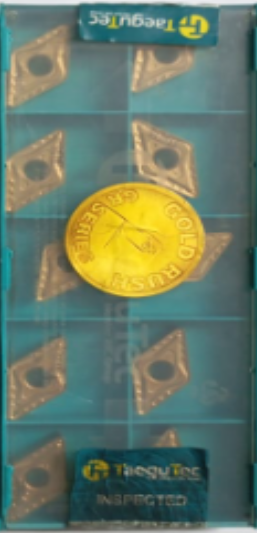

TaeguTec TNMG 130408 PC TT5080

The TaeguTec TNMG 130408 PC TT5080 is a robust 60° triangular turning insert built for demanding stainless steel and exotic alloy turning. Featuring a fine-grain carbide substrate, advanced TiAlN+TiN coating, and durable TNMG geometry, it delivers extended tool life, high wear resistance, and excellent finish for efficient production.

The TaeguTec TNMG 130408 PC TT5080 is a precision-engineered carbide turning insert under the RHINOTURN® TNMG-PC series. Ideal for medium to semi-finishing operations on steels and automotive components, it blends geometry strength with an advanced coating for consistent performance.

🔥 Upgrade to TaeguTec TNMG 130408 PC TT5080—your key to longer cutting life, smoother finishes, and lower cost per component.

Key Features

-

Geometry: Negative 60° triangular TNMG 130408—durable and stable design ideal for turning operations.

-

Grade & Coating: TT5080 with TiAlN + TiN multilayer—optimized for wear resistance, reduced oxidation, and longevity in severe machining conditions.

-

Dimensions & Performance:

-

Thickness (S): ~4.76 mm

-

Inscribed Circle (IC): ~7.94 mm

-

Corner radius (RE): 0.8 mm

-

Max feed: ~0.4 mm/rev; Min: ~0.13 mm/rev

-

Depth of cut capability: up to 3 mm

-

Why It’s a Best Seller

-

Long Tool Life: Advanced TT5080 grade with durable coating resists wear, heat, and adhesion, lowering tool change frequency.

-

Consistent High-Quality Finish: Sharp cutting edges preserve performance over long runs, enhancing surface finish.

-

Reliable in Tough Conditions: Excels in stainless steel and exotic alloy applications with high load resistance and operational consistency.

Application

Perfect for use in:

-

Automotive – precision turning of steel and alloy components.

-

Aerospace – components in stainless and high-temp alloys.

-

Die & Mold – machining demands that require precision and durability.

-

General Engineering – shafts, housings, fasteners, and more.

Benefits

• Automotive

• Aerospace

• Die & Mold

• General Engineering

Order Now

You May Also Like

Frequently Asked Questions

Engineered for medium to semi-finishing turning of stainless steel and automotive parts with reliable edge performance.

A TiAlN+TiN PVD coating that provides exceptional wear and oxidation resistance, extending tool life under tough machining conditions.

Thickness: ~4.76 mm; IC: ~7.94 mm; Corner Radius: 0.8 mm; Feed capacity: 0.13–0.4 mm/rev; Depth of cut: up to 3 mm.

TNMG geometry ensures rigidity and stability, maintaining edge strength even in interrupted cuts or demanding operations.

Available at CNC Tools Depot – India’s Largest Marketplace for Carbide Inserts. Reach out via WhatsApp, DM, or Call for pricing, stock, and bulk order details.