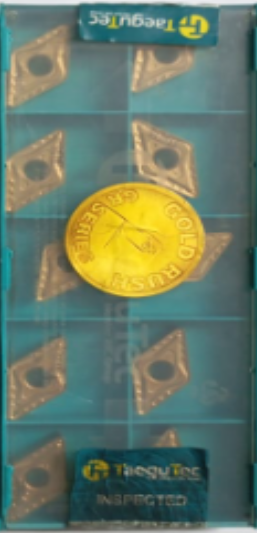

CNMG 120412 MT TT5100

High-performance CNMG 120412 MT TT5100 insert from TaeguTec—80° rhombic, TT5100 grade with TiCN+Al₂O₃+TiN coating. Optimized for medium-rough turning of steel and stainless steel, offering long tool life and superior surface finish. DM/Come in now!

CNMG 120412 MT TT5100 by TaeguTec is a high-quality, negative-80° rhombic carbide insert designed for medium-rough turning of steels and stainless steels. Key parameters:

-

Geometry: CNMG-MT (80° rhombic, negative, medium rough)

-

Inscribed Circle (IC): 12.7 mm

-

Thickness (S): 4.76 mm

-

Corner Radius (RE): 1.2 mm

-

Cutting Edge Length (L): 12.9 mm

-

Depth of Cut (APMX): Up to 5 mm

-

Feed Range: 0.2–0.55 mm/rev

-

Grade: TT5100

-

Coating: Triple layer TiCN + Al₂O₃ + TiN for enhanced wear resistance webshop.taegutec-india.comwebshop.taegutec.es

This insert excels by delivering extended tool life, reduced downtime, high wear resistance, and improved surface finish during turning operations on steel and stainless steel—making it a trusted best‐seller among machinists seeking productivity and reliability. Ideal across industries like automotive, aerospace, die & mold, and general engineering.

Lead-Generation

Lead-Generation Close

Send us a WhatsApp to check today’s price & availability.

Hook

Hook / Attention Line

Longer tool life + higher feeds = lower cost per part. Meet your new go-to turning insert.

Key Features

Key Features & Specs

-

80° rhombic CNMG MT geometry—great for medium-rough turning

-

12.7 mm IC, 4.76 mm thickness, 1.2 mm corner radius, 12.9 mm edge length

-

Handles up to 5 mm cut depth, feeds from 0.2 to 0.55 mm/rev

-

Grade TT5100 with TiCN + Al₂O₃ + TiN triple coating for top wear resistance

-

Best for steel & stainless-steel turning

Why It’s a Best-Seller

Why It’s a Best-Seller

Less machine stoppage, more finished parts—thanks to its robust coating and stable geometry, CNMG 120412 MT TT5100 resists wear and delivers consistent finishes—so you run longer, machine smoother, and cost per piece drops.

Application Industries

Application Industries

Automotive • Aerospace • Die & Mold • General Engineering

You May Also Like

Frequently Asked Questions

It’s optimized for medium-rough turning of steel and stainless steel—thanks to its TT5100 grade and tough triple-layer coating

Maximum depth of cut is 5 mm; recommended feed range is 0.2–0.55 mm/rev

It uses a multi-layer TiCN + Al₂O₃ + TiN coating, offering superior wear resistance and heat protection

It delivers longer tool life, fewer interruptions, and consistently high-quality surface finishes—helping reduce overall machining costs.

Widely used in automotive, aerospace, die & mold, and general engineering applications for reliable, cost-effective turning.