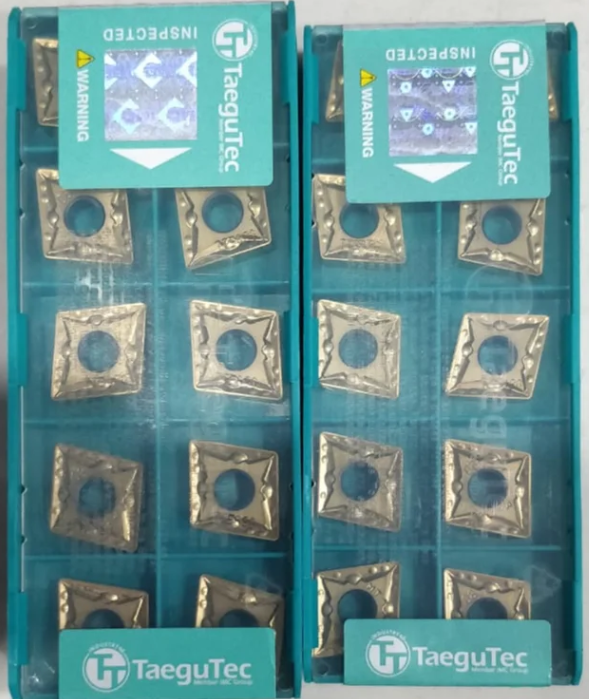

TaeguTec CCMT 09T308 MT TT8020

Discover the TaeguTec CCMT 09T308 MT TT8020 — a high-performance, PVD-coated carbide insert built for medium to rough turning of steel, stainless, and cast iron. Durable, reliable, and cost-efficient for workshops across India.

Take your turning performance to the next level with the TaeguTec CCMT 09T308 MT TT8020, a premium carbide insert trusted by machinists worldwide. Engineered with precision and backed by TaeguTec’s advanced coating technology, this insert is designed to deliver longer tool life, stable cutting, and reduced cost per component.

The CCMT geometry offers a positive cutting angle with excellent chip control, making it ideal for medium to semi-rough turning operations. Its optimized edge strength ensures stable machining even under moderate interruptions.

🔧 Hook / Attention Line

Slash your cost per component and run unattended longer — the TaeguTec CCMT 09T308 MT TT8020 delivers exceptional tool life, lower downtime, and consistent surface finish even under tough turning conditions.

Key Features & Specs

-

Geometry: Positive 80° rhombic (CCMT-MT family), 7° clearance angle

-

Inscribed Circle (IC): 9.52 mm, Thickness (S): 3.97 mm

-

Cutting Edge Length (L): 9.7 mm

-

Corner Radius (RE): 0.8 mm

-

Max Depth of Cut (ap max): 3.5 mm

-

Feed range: ft(min) = 0.13 mm/rev to ft(max) = 0.30 mm/rev

-

Grade / Coating: TT8020, PVD / TiCN-type coating tailored for steel, stainless, and cast iron

-

Best used in turning operations (external turning, medium to rough cuts)

Why It’s a Best Seller

-

High wear resistance: The TT8020 grade offers excellent adhesion and durable performance even when machining hardened steels or tough alloys.

-

Stable cutting under load: Its robust geometry handles moderate interruptions and varying cuts, reducing insert chipping.

-

Reduced downtime: Longer insert life means fewer tool changes, keeping your machines running.

-

Improved surface quality: Delivers consistent finishes from batch to batch, reducing rework.

-

Versatile & reliable: Ideal for turning many common materials — you get one insert for multiple jobs.

Application Industries

Used heavily in:

-

Automotive components (shafts, housings, axles)

-

Aerospace parts (steel alloys, structural components)

-

Die & mold manufacturing (rough turning of mold inserts, cores)

-

General engineering workshops working on cast iron, alloy steel, stainless batches

📞 Call-to-Action

You May Also Like

Frequently Asked Questions

It’s optimal for steel, stainless steel, and cast iron in medium to medium-rough turning operations.

Yes — the positive geometry and robust TT8020 grade help it withstand moderate interruptions. It’s built for stability in less-than-ideal cutting conditions.

Depth of cut (ap) up to ~3.5 mm, feed from 0.13 to 0.30 mm/rev, depending on material and toolholder setup.

Because the performance consistency, wear resistance, and predictable life reduce unplanned stoppages, scrap, and quality issues — ultimately lowering total cost, not just per-unit price.

Typically supplied in packs of 10 (depending on SKU) — get in touch via DM, WhatsApp, or call to confirm current stock and order quantity.