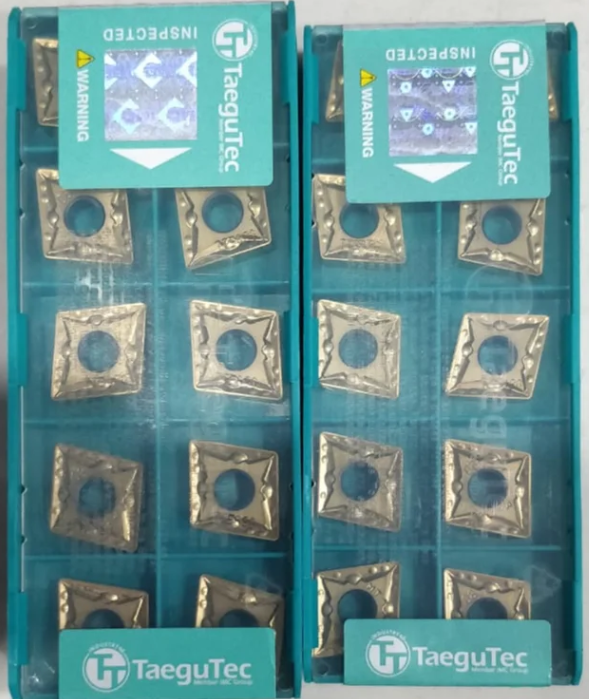

TaeguTec CCMT 060204 FG TT8020

TaeguTec CCMT 060204 FG TT8020 – Positive 80° rhombic finish/medium-light turning insert with TiCN coating, RE 0.4 mm, IC 6.35 mm; ideal for steel & stainless steel finishing applications.

“Upgrade your finishing operations — the TaeguTec CCMT 060204 FG TT8020 gives you smoother surfaces, longer edge life, and less insert changes!”

The TaeguTec CCMT 060204 FG TT8020 is the high-precision finishing/medium-light turning insert engineered for machinists who demand top quality surface finish, consistent edge life, and reduced tooling costs. Perfect for steel and stainless steel components, this insert excels where clean, fine finishes and reliable performance matter most.

🔑 Key Features

-

Geometry: CCMT-FG — Positive 80° rhombic shape, 7° clearance angle. Designed for finish to medium-light turning of steels & stainless steels.

-

Grade & Coating: Grade TT8020, with a TiCN coating. Offers good hardness, wear resistance, and optimized for finish-to-light turning operations.

-

Dimensions & Cutting Parameters:

• Inscribed Circle Diameter (IC): 6.35 mm

• Thickness (S): 2.38 mm

• Corner Radius (RE): 0.4 mm

• Depth of Cut (ap max): ~1.5 mm; Min Feed: ~0.05 mm/rev; Max Feed ~0.15 mm/rev

Why It’s a Best Seller

-

Less Downtime: The TT8020 grade with TiCN coating resists wear and reduces edge chipping for consistent performance, so fewer insert changes.

-

Better Surface Finish: Sharp corner radius (0.4 mm) and positive geometry deliver fine, clean finishes, especially in steels and stainless steels.

-

High Wear Resistance: Though meant for medium-light finishing, this insert holds up well under moderate cutting speeds and lighter depth of cuts — giving good life, especially when working across many parts.

Performance Advantages

• Fewer insert changes → lower downtime & higher machining efficiency.

• Fine surface finish on turned parts → lesser grinding or polishing needed.

• Consistent performance across many parts → less variation, more predictable output and cost per component.

📞 Order Now

You May Also Like

Frequently Asked Questions

Best suited for steels and stainless steels. The positive geometry and TiCN coating give it strength in these materials for clean finish and longer tool life.

The corner radius is 0.4 mm. This relatively small radius helps produce a smoother surface finish and reduces vibration during finishing passes.

Depth of cut (ap) up to ~1.5 mm in medium-light turning; feed rates from ~0.05 mm/rev to ~0.15 mm/rev depending on desired finish.

TT8020 is optimized for finishing / medium-light operations. It may not last as long in heavy roughing compared to more aggressive / tougher grades, but provides superior edge sharpness, better finishes, and lower risk of edge chipping in light-load operations.

You get authentic TaeguTec product, verified stock, competitive pricing, and bulk order support. Plus, expert advice to select the right insert for your job—helping reduce downtime, improve finish, and lower overall cost per component.