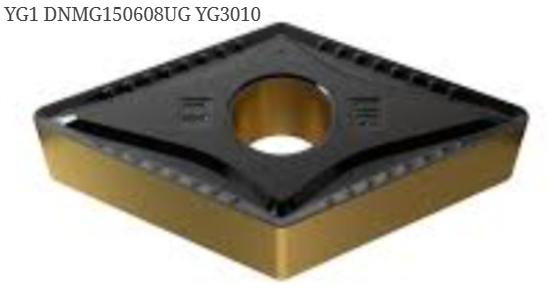

YG1 SPMX07T308 YG602

Get longer tool life and superior surface finish with the YG-1 SPMX07T308-YG602 carbide drill insert—featuring an ST chipbreaker and ultra-dense PVD TiAlN coating for high-performance drilling across stainless steel, cast iron, superalloys, and more.

Boost productivity with longer tool life, better surface finishes, and lower per-part cost—meet the YG-1 SPMX07T308-YG602, engineered for demanding drilling.

Key Features

Key Features & Specs:

-

Geometry & Chipbreaker: ST sharp-geometry chipbreaker tailored for sticky materials like stainless steel Suncoast Precision ToolsMD Traders.

-

Grade & Coating: Premium YG602 grade with ultra-dense PVD TiAlN coating over sub-micron carbide substrate—offers optimal thermal resistance and strength Suncoast Precision ToolsYG-1.

-

Dimensions: Inscribed circle Ø ≈ 0.313″ (7.94 mm); thickness ≈ 0.156″ (3.97 mm); corner radius ~0.8 mm Suncoast Precision ToolsMD TradersYG-1.

-

Applications: Ideal for drilling through steel (< 40 HRC), stainless steel, cast iron, non-ferrous (e.g., aluminium, cobalt), and superalloys like nickel and titanium

Why It’s a Best-Seller:

Why It’s a Best-Seller:

This insert stands out by delivering less downtime, thanks to its durable PVD coating and robust substrate—keeping tool changes and maintenance minimal. The precise ST chipbreaker and sharp geometry deliver a clean surface finish, even on tough-to-machine material. Overall, it cuts costs by extending tool life while maintaining tight tolerances on sticky and abrasive materials.

Industries:

Industries:

Perfect for Automotive (precision holes in stainless & alloy components), Aerospace (superalloy part drilling), Die & Mold (stainless/cast inserts), and General Engineering tasks across varied materials.

Lead-Generation Push:

Lead-Generation Push:

“Send us a WhatsApp to check today’s price & availability!”

You May Also Like

Frequently Asked Questions

Because of its ST chipbreaker geometry, designed to handle sticky materials like stainless—for cleaner chips and smoother drilling

It employs an ultra-dense PVD TiAlN coating over a sub-micron carbide substrate, providing high thermal resistance and durability for demanding applications

Suitable for steel (< 40 HRC), stainless steel, cast iron, non-ferrous metals (like aluminium or cobalt), nickel, titanium, and other superalloys

It features an inscribed circle of approx. 0.313" (7.94 mm), thickness ~0.156" (3.97 mm), and corner radius around 0.8 mm

Its durable build and premium coating mean longer tool life, fewer insert changes, resulting in less downtime and lower cost per component—especially valuable in high-volume or high-precision machining