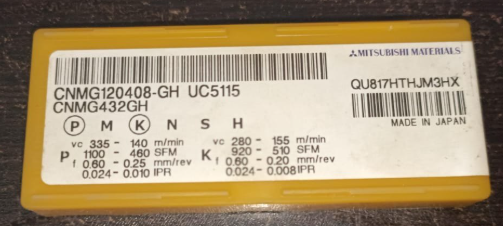

Mitsubishi CNMG120408-GH UC5115

Unleash longer tool life and superb chip control in interrupted cast-iron turning — the Mitsubishi CNMG120408-GH UC5115 insert offers a strong, wear-resistant edge with its advanced TiCN + Al₂O₃ nano-coating. Ideal for automotive, die-mold, and general engineering applications. DM or WhatsApp CNC Tools Depot to check stock & pricing.

🔧 Power Through Cast-Iron Turning with Confidence

Meet the Mitsubishi CNMG120408-GH UC5115 — engineered for reliable, high-feed, high-stress conditions. With its GH breaker geometry and UC5115 grade, this insert delivers outstanding chipping resistance and long tool life even in tough turning scenarios.

Hook / Attention Line

“Struggling with tool breakage in interrupted cuts? Switch to UC5115 and machine cast iron with total confidence.”

Key Features & Specs

-

Geometry: CNMG 120408 — 80° rhombic negative insert, 4-edged, IC = 12.7 mm, thickness = 4.76 mm.

Corner Radius: 0.8 mm (coded “08”). -

Chip Breaker: GH — built to handle unstable / interrupted cuts, high edge strength, plus a large chip pocket.

-

Grade & Coating: UC5115 — a tough substrate coated with a nano-texture CVD coating: fibrous TiCN + thick, even Al₂O₃ (all-black super-even coat) for high wear resistance and chipping resistance.

Cutting Applications: Primarily turning, especially effective in cast iron and ductile cast iron.

Why It’s a Best Seller

-

Exceptional Durability: The advanced coating gives dramatically increased wear life, while the tough substrate resists fracture — leading to fewer insert changes and less unplanned downtime.

Stable Performance in Challenging Conditions: Thanks to the GH chip breaker, this insert excels in unstable or interrupted cuts, delivering consistent chip control and preventing edge chipping. -

Cost-Efficient Machining: Longer tool life + fewer insert rotations = lower cost per component — saving money in high-volume production.

🏭 Application Industries

-

Automotive: Turning cast-iron engine blocks, brake components, differential carriers.

-

Aerospace / Defense: Components made from ductile iron or similar.

-

Die & Mold: Rough and semi-finish turning of hardened or cast tooling components.

-

General Engineering: Heavy-duty cast-iron work, pump housings, heavy machinery parts.

Related Products

You May Also Like

Frequently Asked Questions

It’s optimized for cast iron and ductile cast iron, thanks to its UC5115 grade and high-edge-strength GH chip breaker.

The GH geometry offers maximum edge strength, making it ideal for interrupted / unstable cuts, scale removal, and high-feed operations.

UC5115 is a CVD-coated carbide grade with a nano-texture coating of TiCN + Al₂O₃. It balances toughness and wear resistance, giving long tool life in demanding jobs

It is a double-sided insert with 4 usable cutting edges per insert — maximizing value per insert.

Simply DM, WhatsApp, or call us with your required quantity. We’ll check current stock, provide pricing, and help you place a bulk or single-order as per your needs.