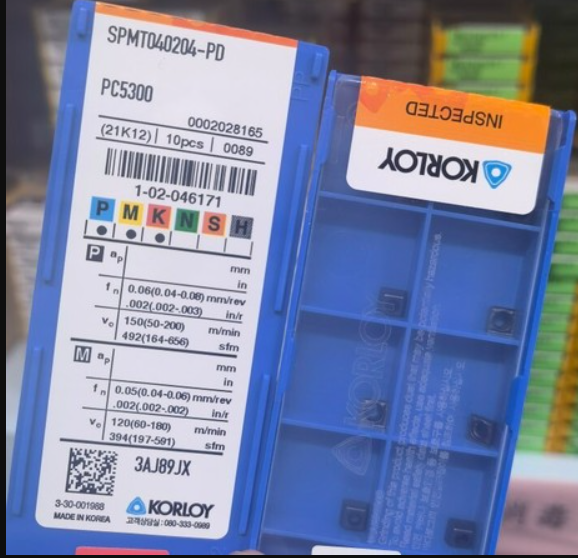

Korloy XOMT07T205-PD PC5300

Meet the Korloy XOMT07T205-PD PC5300 ‒ a PVD TiAlN-coated, PD chip-breaker, universal grade insert with high wear & impact resistance. Offers great performance in drilling / milling / turning across steels, stainless, cast iron & more. Reduce downtime, improve surface finish. #CarbideInserts #CNCTools #Korloy

Attention Machinists & Shops: Want fewer tool changes, better parts finish, and lower cost per component? The Korloy XOMT07T205-PD PC5300 delivers.

Key Features & Specs:

-

Geometry / Style: XOMT-07T205 insert, square / single-sided, PD chipbreaker, 2° relief angle.

-

Grade & Coating: PC5300 — a universal grade with PVD TiAlN coating offering excellent wear & impact resistance in demanding conditions.

-

Size & Mounting: Inscribed circle ~7.8 mm, thickness ~2.8 mm, corner radius ~0.5 mm; fixing hole for screw mount; designed for use in drilling / milling holders (e.g. in Korloy’s KING DRILL systems) for deep hole / through-coolant drill operations.

Why It’s a Best Seller:

-

Longer Tool Life & Less Downtime: The PC5300 grade’s substrate + coating resists wear, chipping and thermal damage so inserts last longer, even under interrupted cuts or moderate turns/drilling. Tests show Korloy drills using XOMT07T205-PD maintain edge integrity far longer than many competitive inserts.

-

Better Surface Finish: The PD chipbreaker & TiAlN coating help produce clean chips, smoother wall/hole surfaces, less flank wear, reducing rework.

-

High Wear & Impact Resistance: Especially in steels, alloys, stainless; able to handle mechanical & thermal stresses. Less tool failure, more predictable machining.

Applications / Industries:

Automotive, Aerospace, Die & Mold, General Engineering, Oil & Gas, Heavy Equipment – any area where precision machining, repeated drilling or mixing of turning / milling is required on steels, stainless steels, cast irons, and alloy materials.

Call-to-Action

You May Also Like

Frequently Asked Questions

It works well on carbon steels, alloy steels, stainless steels, and cast irons. The universal PC5300 grade handles mixed materials, giving good wear & impact resistance.

Yes. In Korloy’s KING DRILL system, the XOMT07T205-PD PC5300 insert is used both as a peripheral and central insert for drills capable of 2D to 5D depths, with good chip evacuation, stability and performance

The PD chip breaker helps produce more consistent, controllable chip shapes under medium feeds / speeds. This reduces risk of built-up edge, chip clogging, and also contributes to smoother surface finish

While exact values depend on machine rigidity, workpiece & coolant, Korloy documentation shows good performance in typical ranges for PC5300 in KING DRILL use under medium to high speed & feed for P, M, K materials. (Always start conservatively, then ramp up.)

Because it reduces downtime (longer life), yields better first-pass surface finish (less rework), and handles tougher materials without frequent insert failure. All of those factors lower your cost per component.