How to Identify Fake or Counterfeit Carbide Inserts

Counterfeit carbide inserts are a hidden—and growing—threat in CNC machining. Fake or mis-labelled inserts can wear out quickly, damage toolholders or workpieces, cause scrap and downtime, and even create safety hazards. This guide explains, step-by-step and in plain language, how to spot counterfeit carbide inserts, how ISO insert nomenclature helps you verify an insert, and what manufacturers (Sandvik, Kennametal, ISCAR and others) publish as best practice for traceability and authentication.

In the world of CNC machining, precision is everything. Whether you are producing automotive components, aerospace parts, or general engineering spares, the smallest deviation in tool geometry can mean the difference between a perfect cut and a scrapped workpiece.

Understanding Carbide Inserts

Carbide inserts are the backbone of modern CNC machining, used across industries like automotive, aerospace, die & mold, and general manufacturing. These tiny cutting tools enable precise turning, milling, and threading operations. However, the rise of counterfeit carbide inserts poses serious risks—shorter tool life, poor surface finish, unexpected tool failure, and even machine damage.

Identifying fake or counterfeit carbide inserts is critical for maintaining productivity, safety, and quality in your CNC operations. This guide will help you recognize genuine inserts, understand their technical specifications, and make informed purchasing decisions.

Understanding Carbide Inserts

Carbide inserts are classified by ISO 1832 standards, which describe their shape, clearance angle, tolerance, chip breaker, and coating. Familiarity with these standards is essential for distinguishing authentic inserts from fakes.

Key Features of Genuine Carbide Inserts

Shape and size: ISO codes like CNMG, VNMG, or SNMX indicate the insert geometry. For example:

CNMG 120408:

- C = 80° diamond shape

- N = 0° clearance angle

- M = medium tolerance

- G = ground insert

Chip breaker design: Influences the type of chip control during cutting. Properly engineered chip breakers are difficult to replicate in counterfeits.

Coatings: PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) coatings enhance wear resistance. Counterfeit inserts often lack uniform coatings or show uneven coloring.

Material quality: Genuine inserts use high-grade tungsten carbide with proper binder content. Fake inserts may have inconsistent hardness or break easily.

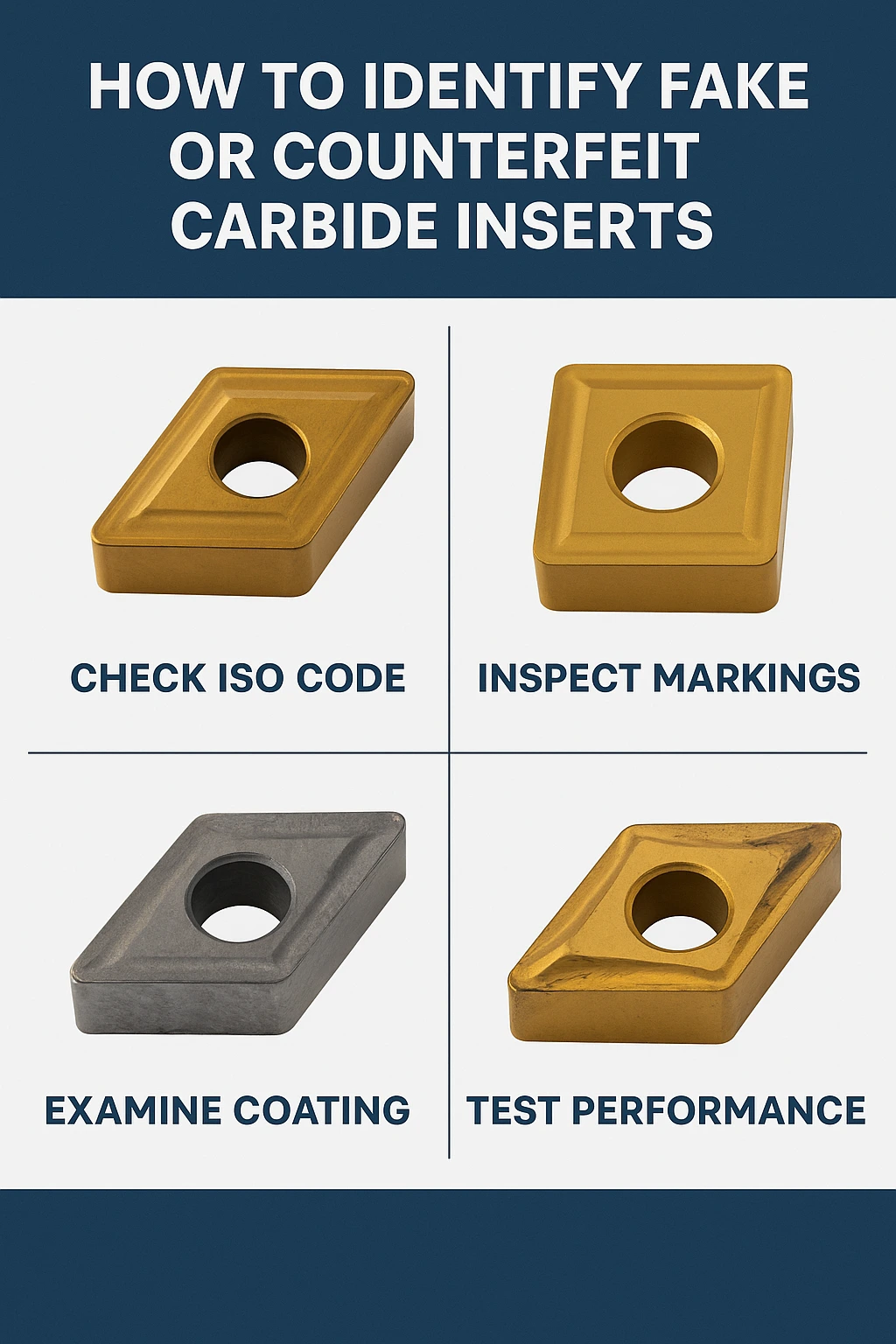

Step-by-Step Guide to Identify Fake Inserts

1. Examine Packaging and Branding

- Look for authentic logos: Leading brands like Sandvik Coromant, Kennametal, Iscar, and Korloy use precise printing and embossing.

- Check serial numbers and QR codes: Many manufacturers now include traceable codes that verify authenticity online.

- Compare with official catalogs: Verify insert specifications and packaging against the brand’s official documentation.

2. Inspect ISO Markings on Inserts

Genuine inserts have ISO codes and grade markings laser-etched, not stamped or printed.

Example: VNMG 160404-VM NC3120

- VNMG = 80° rhomboid, 0° clearance, medium tolerance, ground insert

- NC3120 = grade and coating information (NC3120 is Korloy’s PVD grade for steel)

Check the etching clarity, alignment, and font consistency.

3. Assess Physical Quality

- Edge sharpness: Authentic inserts have uniform cutting edges. Fakes may have inconsistent edge geometry.

- Surface finish: Genuine inserts exhibit smooth, even surfaces; rough or pitted surfaces indicate lower-quality production.

- Weight and density: Substandard carbide inserts may feel lighter or inconsistent in density.

4. Analyze Coatings and Color

- Authentic PVD or CVD coatings appear uniform and bright.

- Fakes may have uneven coating layers, scratches, or unusual discoloration.

5. Test Performance (Optional for High-Volume Users)

- Conduct trial cuts on non-critical material. Counterfeit inserts often fail prematurely, generate poor surface finishes, or produce inconsistent chips.

Practical Applications and Industry Examples

- Automotive machining: High-speed steel and carbide inserts are used for engine components and transmission parts. Counterfeit inserts risk catastrophic tool failure.

- Aerospace components: Titanium and superalloy machining demand precision inserts; fakes can cause dimensional errors.

- Die & mold industries: Inserts must withstand high cutting forces; counterfeit inserts reduce tool life and precision.

- General CNC machining: Everyday turning and milling operations rely on authentic inserts for efficiency and repeatability.

Comparing Top Brands

| Feature | Sandvik Coromant | Kennametal | Iscar | Notes |

|---|---|---|---|---|

| Chip breaker design | Optimized for steel | Excellent for tough metals | Versatile for light/medium cuts | All genuine inserts follow ISO codes |

| Coating options | PVD & CVD | PVD/CVD & multi-layer | PVD | Counterfeits often miss multi-layer coatings |

| Traceability | QR codes & batch numbers | Serial numbers | Holograms & codes | Always verify with the manufacturer |

Neutral comparison helps spot suspicious inserts that lack standard features.

Conclusion

Counterfeit carbide inserts are not just a nuisance—they can cause serious damage to machines, reduce productivity, and increase costs. By understanding ISO insert nomenclature, checking physical and chemical features, and buying from trusted sources like CNC Tools Depot, you ensure genuine products that enhance tool life, efficiency, and safety.

Explore our marketplace for authentic carbide inserts from top brands, verified for quality and ISO compliance.

Frequently Asked Questions

It’s an ISO designation: C = 80° diamond, N = 0° clearance, M = medium tolerance, G = ground insert. The numbers that follow give size, thickness, and radius.

Check ISO code accuracy, packaging quality, traceability codes, coating finish, and chipbreaker design. Counterfeits usually fail one or more of these checks.

Coatings extend tool life. If an insert claims to be CVD-coated but looks thin and weak, it might be counterfeit.

Not always—some brands are cheaper. But if the price is too low for a premium brand, it’s a red flag.

From authorized distributors or trusted marketplaces like CNC Tools Depot, which partners with OEM-approved suppliers.