A Guide to Carbide Insert Coatings: PVD, CVD, and More

Explore the different carbide insert coatings like PVD, CVD, and multi-layer options. Learn their benefits, ISO codes, and applications in turning, milling, and CNC machining.

In the world of CNC machining, the performance of carbide inserts can make or break productivity. One of the most critical factors influencing tool life, cutting efficiency, and surface finish is the coating on these inserts. From PVD (Physical Vapor Deposition) to CVD (Chemical Vapor Deposition) and other specialized coatings, understanding the differences can help engineers, machinists, and hobbyists select the right tool for turning, milling, and other metalworking operations.

Coatings not only extend the life of inserts but also allow them to cut harder materials like stainless steel, titanium, and superalloys with precision. This guide simplifies carbide insert coatings, explains technical jargon, and provides practical examples for real-world applications.

What Are Carbide Insert Coatings?

A carbide insert coating is a thin layer applied to the surface of a tungsten carbide insert to improve its wear resistance, heat tolerance, and friction properties. Think of it as a protective armor that helps the insert withstand extreme cutting conditions.

Common benefits of coatings include:

- Reduced friction for smoother cuts

- Increased hardness for longer tool life

- Resistance to oxidation at high temperatures

- Improved chip evacuation

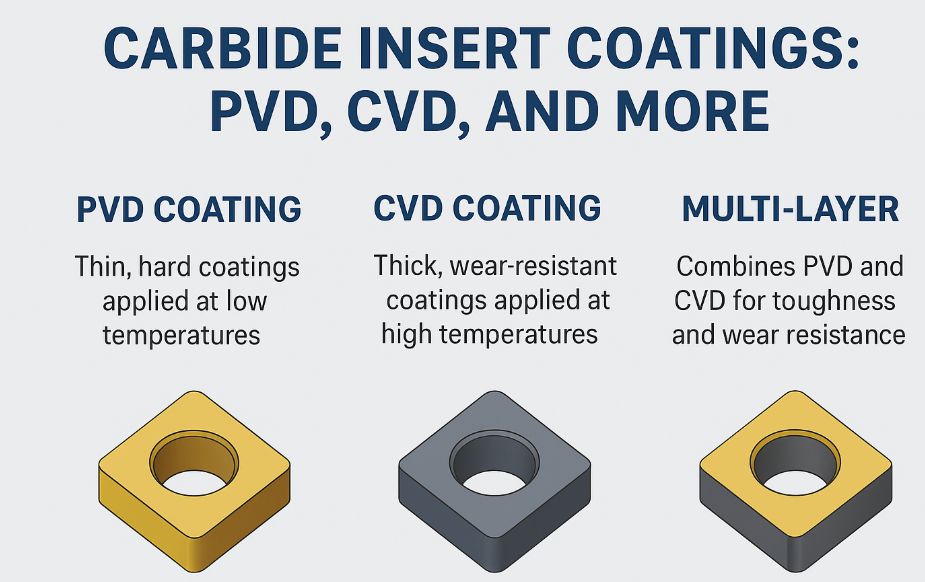

Types of Carbide Insert Coatings

1. PVD Coating (Physical Vapor Deposition)

PVD coatings are applied at relatively low temperatures using a vacuum deposition process. Popular PVD coatings include TiN (Titanium Nitride), TiCN (Titanium Carbonitride), and AlTiN (Aluminum Titanium Nitride).

Key Features:

- Thin coating (2–5 µm)

- High hardness and wear resistance

- Best for finishing operations and high-speed milling

Practical Use:

- Ideal for stainless steel and alloy steels

- Common in automotive and aerospace industries

2. CVD Coating (Chemical Vapor Deposition)

CVD coatings are applied at higher temperatures, forming a thicker layer (3–8 µm) on the insert surface. Examples include TiC (Titanium Carbide), TiCN, and Al2O3 (Aluminum Oxide).

Key Features:

- Excellent wear and heat resistance

- Suitable for roughing and heavy-duty operations

- Slightly less sharp edge than PVD inserts

Practical Use:

- Best for cast iron, hardened steels, and high-temperature alloys

- Used in die & mold and general machining applications

3. Multi-Layer Coatings

- Some inserts combine PVD and CVD layers to achieve a balance of toughness and wear resistance. These are especially effective in high-speed milling and interrupted cutting operations.

4. Other Specialty Coatings

- Diamond Coating: Ultra-hard, ideal for non-ferrous metals and composites

- TiAlN / AlCrN: High oxidation resistance, excellent for dry machining

Understanding ISO Carbide Insert Codes

The ISO 1832 standard helps identify inserts based on shape, clearance, tolerance, chip breaker, and coating.

Example: CNMG 120408

- C = 80° diamond shape

- N = 0° clearance angle

- M = Medium tolerance

- G = Ground insert

- 12 = Size (inscribed circle 12 mm)

- 04 = Thickness (4 mm)

- 08 = Nose radius (0.8 mm)

Tip: When choosing a coated insert, always match the coating type with your material and operation.

Practical Applications of Coated Inserts

| Industry | Common Materials | Recommended Coating | Insert Type |

|---|---|---|---|

| Automotive | Stainless Steel, Alloy Steel | PVD TiAlN | Turning Inserts |

| Aerospace | Titanium, Superalloys | CVD Al2O3 | Milling Inserts |

| Die & Mold | Hardened Steel | Multi-Layer PVD/CVD | Indexable Inserts |

| General Machining | Cast Iron, Carbon Steel | TiCN | All-purpose inserts |

Brand Comparison:

- Sandvik Coromant: High-performance multi-layer coatings, especially for finishing stainless steel

- Kennametal: Excellent CVD-coated inserts for roughing hardened steels

- Iscar: Broad selection of PVD-coated inserts for high-speed milling and finishing

Conclusion

Choosing the right carbide insert coating can dramatically improve your CNC machining efficiency, extend tool life, and reduce costs. Whether it’s PVD for finishing, CVD for heavy-duty cutting, or multi-layer inserts for a balance, understanding coatings is key.

Explore CNC Tools Depot’s marketplace today to find high-quality, brand-certified carbide inserts for all your turning and milling operations.

Frequently Asked Questions

PVD stands for Physical Vapor Deposition, a low-temperature coating process that increases hardness and wear resistance, ideal for finishing operations.

CVD (Chemical Vapor Deposition) applies a thicker, heat-resistant coating at high temperatures, making it suitable for heavy-duty cutting and roughing.

PVD coatings like TiAlN or TiCN are preferred due to their hardness and lower friction, which prevent work hardening.

It depends. Geometry and coating matter. Some multi-purpose inserts can work for both, but specialized inserts give better performance.

CNC Tools Depot stocks all leading brands, provides verified technical data, and offers expert guidance to help you choose the right ISO-coded, coated insert for your operation.